Table of Contents

ToggleFood packaging machines are devices designed to automate the packaging process in the food industry. These machines are specifically engineered to efficiently package various types of food products, ensuring product safety, quality, and integrity throughout the packaging process.

Food packaging machines encompass a wide range of equipment, from simple manual machines to fully automated systems. These machines perform tasks such as filling, sealing, wrapping, labeling, and coding food products. They are designed to handle different types of food packaging materials, including plastic, paper, metal, and glass.

Additionally, food packaging machines play a crucial role in ensuring food safety. They are designed to meet industry standards and regulations, including hygiene and sanitation requirements. These machines incorporate features that minimize the risk of contamination and protect food products from external contamination sources, such as dust, bacteria, and insects.

Food packaging machines can also enhance productivity and efficiency in food packaging operations. By automating the packaging process, these machines can significantly increase production output, reduce labor costs, and minimize human errors. Furthermore, these machines can be easily integrated into existing production lines, enabling seamless operation and improving overall workflow.

Overall, food packaging machines are essential tools in the food industry, allowing food manufacturers to package their products efficiently, maintain product quality and safety, and meet consumer demands. These machines not only streamline the packaging process but also help businesses achieve higher productivity and profitability.

Flow wrapping machines are versatile and efficient packaging machines widely used in the food industry. These machines automate the process of wrapping products in a tight, protective film, creating a sealed package that extends the shelf life of food products and maintains their freshness.

The benefits of using flow wrap machine for food packaging are far-reaching. Firstly, these machines offer exceptional flexibility, accommodating various product shapes and sizes. Whether it is bakery items like bread and cakes, confectioneries such as chocolates and candies, or even fresh produce like fruits and vegetables, flow wrap packaging machine can securely package them all. This versatility allows manufacturers to streamline their packaging operations and meet consumer demands more efficiently.

Moreover, horizontal flow wrap machine ensure a tight seal around the food product, protecting it from contamination and preserving its taste and texture. Through a combination of heat sealing and film tensioning, these machines create a secure barrier that prevents oxygen and moisture from affecting the product’s quality. This airtight packaging not only enhances food safety but also extends the shelf life, reducing waste and providing consumers with fresher products for a longer duration.

In today’s fast-paced society, convenience plays a crucial role in the purchasing decisions of consumers. Flow wrapping machines excel in this aspect by enabling the packaging of food products in individual portions or small servings. This packaging format enhances convenience, allowing consumers to grab a quick snack or portion-controlled meals with ease. Additionally, flow wrapping machines can create resealable packages, enabling customers to consume a portion of the product and save the rest for later, ensuring freshness and minimizing waste.

Numerous food products are commonly packaged using flow wrapping machines, which highlights their widespread applicability. Snack foods like granola bars, cookies, and potato chips are frequently packaged using this method. Flow wrapping machines are also employed for packaging single-serve items like yogurt cups, chocolate bars, and energy bars. Bakery items such as sliced bread, croissants, and muffins are typically wrapped using flow wrapping machines for maximum freshness. Moreover, flow wrapping is widely utilized for wrapping fresh produce like lettuce, cucumbers, and carrots, ensuring their quality and extending their shelf life.

In conclusion, flow wrapping machines have revolutionized food packaging by providing manufacturers with a versatile, efficient, and convenient solution to package a wide range of food products. With their ability to create airtight seals, extend shelf life, and accommodate different product shapes and sizes, flow wrapping machines are becoming an indispensable tool for the food industry. From snack foods to fresh produce, these machines play a vital role in ensuring product quality, reducing waste, and meeting consumer demands.

One of the key players in the field of primary packaging machines is the vacuum packaging machine. This remarkable equipment plays a crucial role in extending the shelf life of various food products while maintaining their quality and freshness. Let’s delve into the world of vacuum packaging and explore its advantages as well as the food products that commonly benefit from this packaging technique.

Vacuum packaging machines are designed to remove air from the packaging environment before sealing the product. By eliminating oxygen, these machines create a vacuum, sealing the product in an airtight package. This process significantly reduces the risk of spoilage from oxidation, as many microorganisms responsible for food spoilage and deterioration require oxygen to thrive.

One of the prime advantages of vacuum packaging machines lies in their ability to extend the shelf life of food products. By removing oxygen, these machines inhibit bacterial growth, which in turn slows down the degradation process. Foods packaged using this technique can last longer without compromising their quality, taste, and nutritional value. Vacuum packaging also helps to preserve the natural color, texture, and aroma of the food, enhancing the overall visual appeal and gustatory experience for consumers.

Additionally, vacuum packaging contributes to minimizing food waste. By extending the shelf life, it allows for inventory management and reduces the need for premature disposal of perishable items. As a result, businesses can experience reduced financial losses and contribute to a more sustainable approach to food distribution and consumption.

Various food products benefit from vacuum packaging. Fresh meats, such as beef, poultry, and seafood, are commonly vacuum-sealed to slow down spoilage, retain their juiciness, and prevent freezer burn. Similarly, cheese, both hard and soft varieties, is often vacuum packaged to keep it in optimal condition for an extended period. Additionally, fruits and vegetables can be vacuum sealed to maintain their freshness, crispness, and flavor, improving their overall shelf life.

Moreover, vacuum packaging machines are highly effective in preserving baked goods like bread, cakes, and pastries. By removing the air, these machines help prevent the growth of mold, keeping the products intact and delicious for a more extended duration.

In conclusion, vacuum packaging machines offer an exceptional solution for extending the lifespan of various food products, while preserving their original characteristics. By eliminating oxygen from the packaging environment, these machines inhibit bacterial growth and reduce the risk of spoilage. Consequently, foods maintain their taste, appearance, and nutritional value for an extended period. From fresh meats and cheese to fruits and vegetables, vacuum packaging machines are an invaluable asset for food producers and distributors in ensuring their products reach consumers with utmost freshness and quality.

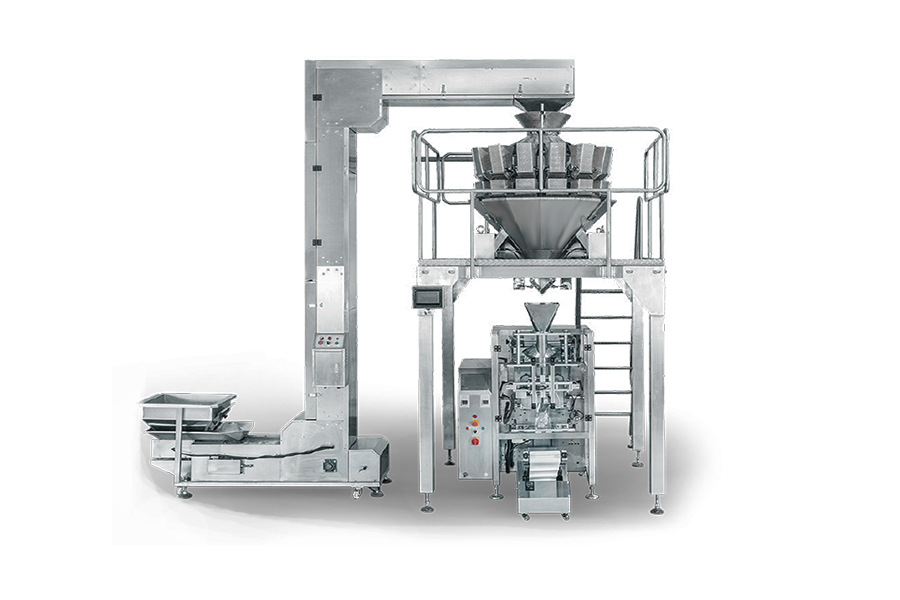

Form-fill-seal (FFS) machines have become an integral part of the packaging process in the food industry. These advanced automated systems are designed to create, fill, and tightly seal packages, delivering a streamlined packaging solution from start to finish. Let’s delve into the workings of these remarkable machines, the advantages they offer to the food industry, and the food products that are commonly packaged using them.

Form-fill-seal machines essentially combine three primary functions into one fluid process. First, they form the packaging material into the desired shape, creating a pouch or container. Then, they precisely measure and fill the product into the formed package. Finally, they seal the package with heat, adhesive, or other sealing mechanisms, ensuring product safety and longevity. This all-in-one process takes place seamlessly and quickly, resulting in increased efficiency and productivity.

There are various advantages associated with using form-fill-seal machines in the food industry. Firstly, their high-speed operation allows for rapid packaging, enabling manufacturers to meet consumer demands in a timely manner. This not only keeps production lines running smoothly but also ensures a consistent supply of products in the market. Secondly, FFS machines offer superior package integrity. By creating a strong seal that protects the product from external factors such as moisture, oxygen, and contaminants, these machines help extend the shelf life of food products. This, in turn, reduces waste and enhances the overall quality of packaged foods. Additionally, FFS machines are versatile and flexible, accommodating a range of package sizes, shapes, and materials. This adaptability allows food manufacturers to cater to different market requirements and effectively package a diverse range of products.

Form-fill-seal machines find widespread utilization across the food industry, with numerous food products packaged using this technology. Examples include dry or powdered goods like coffee, spices, flour, and sugar, which are efficiently measured and filled into packages of various sizes. Liquid products such as beverages, sauces, and condiments are also commonly packaged using FFS machines. Moreover, perishable food items such as fresh produce, dairy products, and meat are often packaged using modified atmosphere packaging (MAP) techniques. This involves creating a controlled atmosphere within the package that extends the product’s shelf life. FFS machines excel in performing this process, making them highly sought after in the food industry.

In conclusion, form-fill-seal machines have revolutionized the way food products are packaged, offering a host of advantages to the food industry. Their ability to seamlessly form, fill, and seal packages ensures efficiency, quality, and product safety. From dry goods to liquid items and perishable items, FFS machines continue to play a vital role in packaging a wide range of food products. Embracing these advanced packaging solutions not only benefits manufacturers but also the end consumers by delivering quality and freshness in every package.

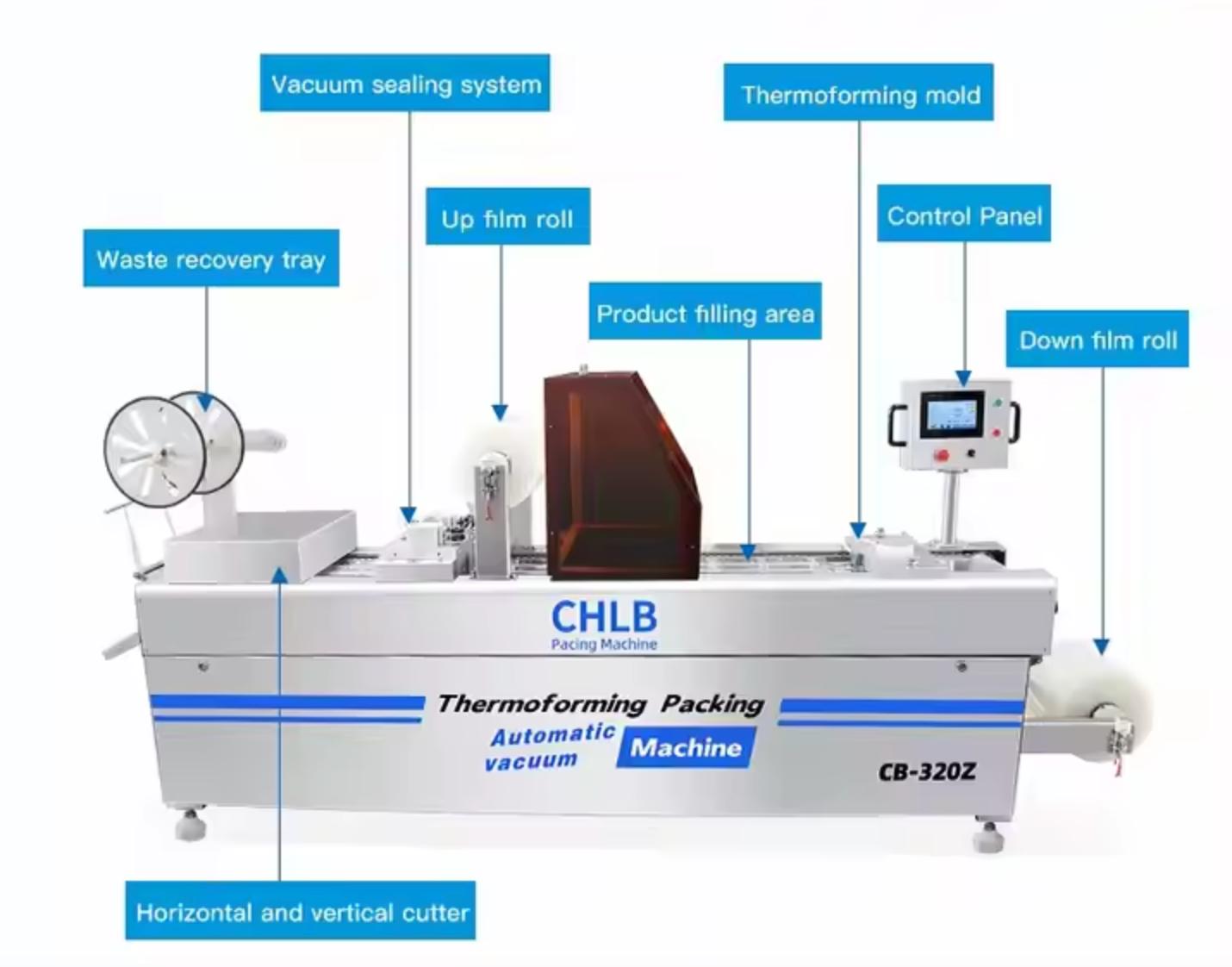

thermoforming packaging machines are an essential component of primary packaging systems in the food industry. These machines are specifically designed to securely seal food products within a tray, providing an airtight and tamper-evident packaging solution. Let’s delve deeper into thermoforming packing machines to understand their functionality and significance in the food packaging process.

Thermoforming packaging machines are mechanical devices used to seal food products in pre-formed trays made of materials such as plastic, aluminum or cardboard. These machines automate the process of placing the product in the tray, sealing it and usually applying a top film or lidding material. Sealing is achieved by heat, which melts the tray material, forming a seal that is either vacuum- or MAP-enabled to preserve the product’s freshness and extend its shelf life.

Thermoforming packaging machines provide a high level of product protection by creating a secure barrier that keeps out moisture, gases and external contaminants. This helps maintain the integrity and quality of food, reducing the risk of spoilage or contamination during storage and transportation.

The robust seal created by tray sealing machines acts as a protective shield, preventing the entry of oxygen and maintaining a controlled environment for food products. This extends the shelf life of perishable items, ensuring they remain fresh and desirable for a longer duration.

Thermoforming packing machines allow for attractive and customized packaging designs. The top film or lidding material can be printed with product-related information, branding elements, and eye-catching graphics, enhancing the overall visual appeal of the food product and strengthening its brand identity.

Thermoforming packaging machines are extensively used for packaging ready-to-eat meals, such as salads, pre-cooked pasta dishes, or meat-based preparations. These machines ensure the freshness and cleanliness of the meals, making them convenient options for consumers on-the-go.

Thermoforming vacuum packaging is a popular technique for packaging fresh fruits and vegetables, offering an efficient and visually appealing way to display and store produce. The seal keeps the contents crisp and vibrant while protecting them from external factors that may lead to spoilage.

Products like yogurt, cottage cheese, and individual portions of butter are commonly packaged using thermoforming package machines. These machines guarantee a tight seal that prevents contamination, maintaining the quality and purity of dairy products until they reach the consumer’s table.

In summary, thermoforming package machines play a crucial role in the primary packaging process for food products. Their ability to create a hermetic seal, provide product protection, extend shelf life, and facilitate branding make them a preferred choice for a diverse range of items, including ready-to-eat meals, fresh produce, and dairy products.

Case packing machines play a crucial role in the packaging process of various industries, particularly the food industry. These machines automate the task of grouping products into cases for efficient transportation and storage.

Efficient case packing is of utmost importance in the food industry due to several reasons. Firstly, it ensures that the products are securely arranged and protected during transportation and handling. By securely packing products into cases, the chances of damage or breakage are minimized, reducing the risk of spoilage and contamination. This is especially significant when dealing with perishable food items that require careful handling to maintain their quality and safety.

Additionally, efficient case packing facilitates easy inventory management and reduces labor costs. With the help of case packing machines, products can be quickly and accurately counted and organized, speeding up the warehousing processes. This not only streamlines operations but also enables efficient tracking of inventory levels to prevent stockouts or overstocking.

Case packing machines are widely used in the food industry for packaging a variety of products. Some notable examples include canned goods, such as vegetables, fruits, and soups, where the machines ensure the tight arrangement of cans within cases to prevent shifting or damage. Similarly, case packing machines are commonly utilized in the packaging of beverages, such as bottled water, juices, and soft drinks. These machines efficiently group the bottles into cases, ensuring stable and secure positioning.

Other food products that are often packaged using case packing machines include snack items like chips, cookies, and chocolates. By precisely arranging these delicate products, case packing machines preserve their shape and prevent breakage. Additionally, case packaging is used for packed meats, frozen foods, and baked goods, further underscoring the significance of these machines in the food industry.

In conclusion, case packing machines play an essential role in the food industry by automating the process of securely packaging products into cases. The efficient case packing not only ensures the protection and preservation of food items during transportation but also streamlines inventory management and reduces labor costs. With their versatility and widespread use, case packing machines continue to be invaluable tools for packaging various food products.

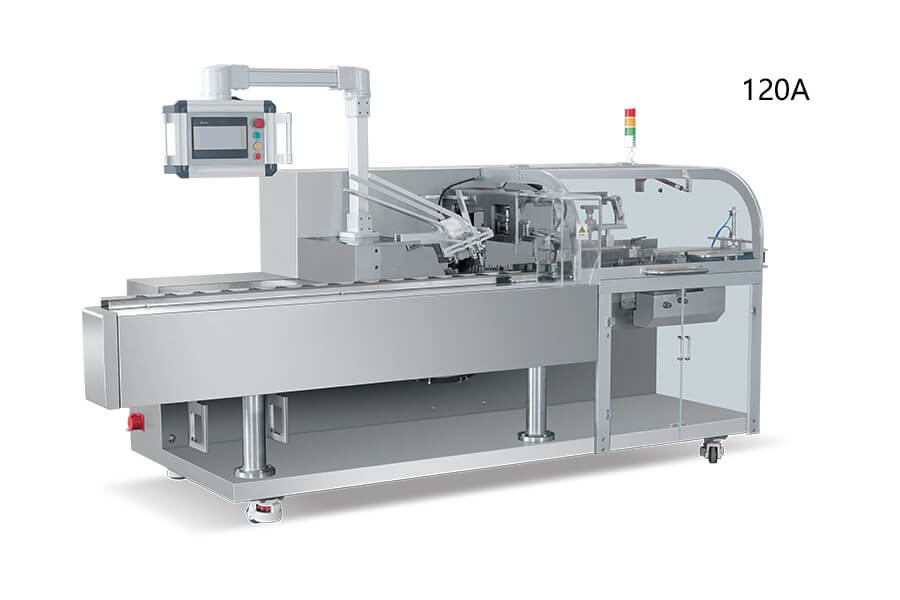

Packaging plays a crucial role in ensuring the safety and presentation of food products. One significant element of secondary packaging is cartoning machines. These advanced machines have brought about a revolution in the way food products are packaged, offering numerous benefits for both manufacturers and consumers.

Cartoning machines, as their name suggests, are specially designed to create cartons or boxes for packaging products. These machines are automated, highly efficient, and capable of handling large volumes of food products. The process begins with the machine folding and sealing the cartons in a precise manner, followed by the insertion of food products into the cartons. Finally, the machines seal the cartons, ready for distribution.

One of the significant advantages of using cartoning machines for food packaging is the speed and accuracy they offer. These machines can package a significant number of products in a short duration of time, reducing production costs and increasing overall efficiency. Additionally, cartoning machines ensure consistent carton quality and sealing, minimizing the risk of product tampering or damage during transportation.

Furthermore, cartoning machines provide versatility in packaging various food products. Their flexibility allows packaging products of different shapes and sizes, such as cereal boxes, beverage cartons, frozen food packages, snack boxes, and more. This adaptability makes cartoning machines an ideal choice for food manufacturers who produce a wide range of products.

The benefits of cartoning machines extend beyond production and convenience. For consumers, these machines ensure that food products reach them in perfect condition. With airtight seals and secure packaging, cartoning machines help maintain the freshness and taste of packaged food, enhancing the overall consumer experience.

Numerous food products are commonly packaged using cartoning machines. Breakfast cereals, for instance, are often sold in cartons, allowing easy pouring and storage. Additionally, beverages such as milk, juice, and soft drinks are safely sealed within cartons, protecting the liquid contents from external factors. Snack boxes, containing items like cookies, chips, and crackers, are another example of food products that commonly utilize cartoning machines.

In conclusion, cartoning machines have revolutionized the packaging industry for food products. Offering speed, accuracy, versatility, and enhanced consumer experience, these machines are a game-changer for food manufacturers. With their capability to package a wide variety of food items, cartoning machines ensure that products reach consumers in perfect condition, maintaining freshness and quality. In the competitive world of food packaging, cartoning machines have indeed become the go-to solution.

Palletizing machines have revolutionized the way goods are stored, transported, and distributed across industries. These sophisticated machines automate the process of palletizing, which involves arranging and stacking products on pallets for efficient storage and transportation. This section will provide a comprehensive understanding of palletizing machines, emphasizing their importance and their applications in the food industry.

Palletizing machines are designed to handle a wide range of products, from cans and bottles to boxes and bags. These machines use advanced robotics and automation technology to precisely place each item on a pallet, creating stable and secure loads. With the ability to handle heavy loads and operate with accuracy, palletizing machines ensure optimum efficiency and safety throughout the palletization process.

The importance of palletizing machines cannot be overstated. Efficient storage and transportation are critical to the success of businesses operating in various industries. By employing palletizing machines, companies can significantly increase productivity and minimize human errors associated with manual palletization.

One of the primary benefits of using palletizing machines is their ability to optimize space utilization. By arranging products in a uniform and compact manner, pallet loads can be stacked higher, making the most of available vertical space in warehouses and distribution centers. This not only leads to cost savings by reducing the need for additional storage space but also streamlines inventory management processes.

Moreover, palletizing machines enable fast and consistent palletization, leading to improved workflow and reduced labor requirements. Time-consuming and physically demanding tasks, such as lifting heavy products and accurately stacking them, are efficiently automated. This not only enhances productivity but also minimizes the risk of worker injuries, creating a safer working environment.

In the food industry, palletizing machines find extensive use due to the high volume of products that need to be handled on a daily basis. Food processors and manufacturers heavily rely on palletizing machines to streamline their packaging, storage, and distribution operations. Various food products, such as canned goods, bottled beverages, packaged snacks, frozen foods, and even fresh produce, are commonly palletized using these machines.

For example, in a beverage manufacturing plant, palletizing machines efficiently stack cases of bottled drinks onto pallets, ready for transport to distribution centers or retail stores. Similarly, in a bakery, palletizing machines effortlessly arrange trays of bread and pastries onto pallets, ensuring proper handling and intact packaging.

In summary, palletizing machines offer unparalleled advantages in terms of efficiency, productivity, and safety in the storage and transportation of various products. The food industry, in particular, heavily relies on these machines to palletize a wide range of food products, ensuring they are securely and conveniently packaged for distribution. By automating the palletization process, businesses can enhance their operations, reduce costs, and ultimately deliver their products to consumers in an efficient and timely manner.

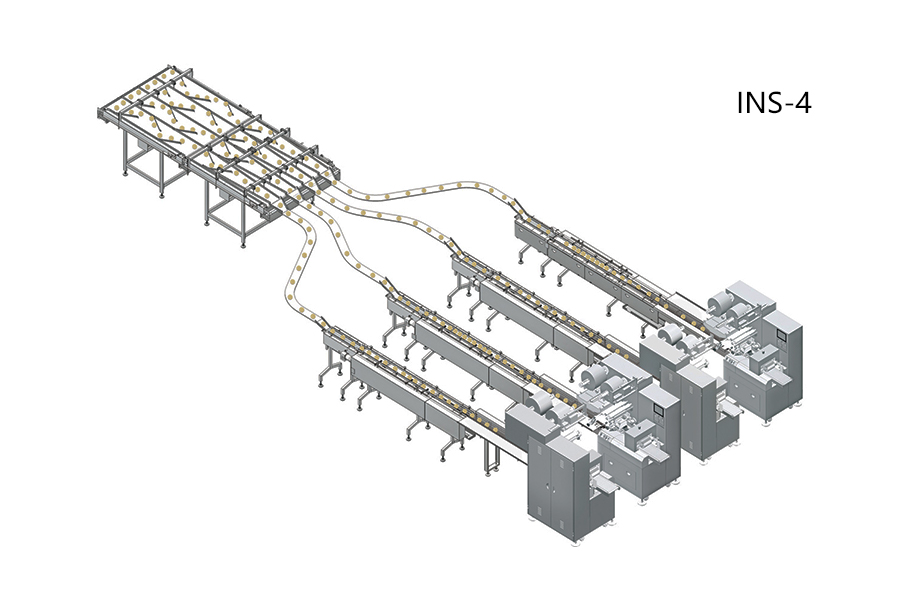

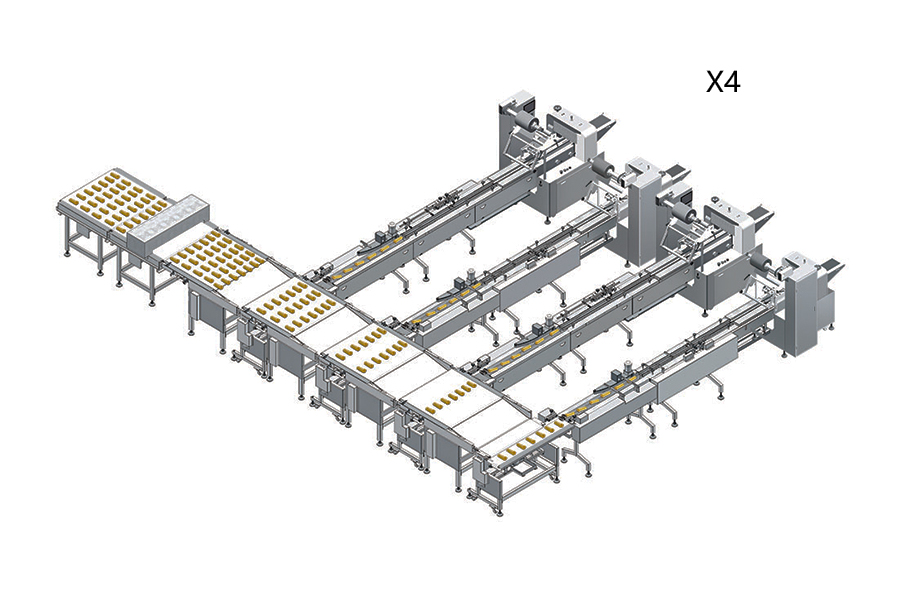

Packing lines refer to integrated systems that automate the packaging process. They encompass various machines, equipment, and conveyors working in harmony to efficiently package products. At the heart of a packing line, you will typically find a packaging machine that performs a specific packaging function such as filling, sealing, labeling, or wrapping. These machines are interconnected, allowing for a continuous flow of products through the entire packaging process.

Packing lines play a crucial role in industries, offering several benefits that contribute to increased productivity and efficiency. Firstly, packing lines eliminate the need for manual labor in packaging operations, reducing human errors and fatigue. They automate repetitive tasks, enabling higher production rates and consistent packaging quality.

Secondly, packing lines optimize space utilization by accommodating multiple machines and conveyors in a compact layout. This allows for a streamlined and organized packaging flow, saving valuable floor space in manufacturing facilities.

Furthermore, packing lines offer flexibility in handling various packaging materials, sizes, and shapes. Through the integration of different machines, the packing line can adapt to the specific needs of different products, ensuring suitability for a wide range of food items.

In conclusion, packing lines are integral to modern packaging operations, streamlining processes, and ensuring the efficient packaging of various food products. By automating tasks, optimizing space, and offering versatility, these systems enhance productivity and enable businesses to meet the demands of today’s fast-paced market.

In this blog, we have discussed various types of food packaging machines that are widely used in the food industry. We explored machines such as form-fill-seal machines, vacuum packaging machines, and cartoning machines, which play a crucial role in efficiently packaging food products.

Choosing the right packaging machine for specific food products and production needs is of utmost importance. Different food products have unique packaging requirements, and selecting the appropriate machine ensures that these requirements are met effectively. This not only helps in maintaining the quality and freshness of the food but also increases productivity and reduces wastage.

Looking ahead, the future of food packaging machines in the food industry seems promising. With advancements in technology, we can expect to see more automated and intelligent packaging machines. These machines will not only enhance the packaging process but also provide valuable data for improving efficiency and sustainability.

Overall, investing in the right packaging machine and keeping up with emerging technologies will undoubtedly be beneficial for food manufacturers and ensure the highest standards of product quality and customer satisfaction.

Sourcing bag packaging machines? You will get a free quote or get more details about the solution from our experienced experts.

To receive the optimal free package solution tailored to your needs, kindly complete and submit the form below.