Sealing machines play a crucial role in various industries by ensuring product freshness, improving packaging quality, and enhancing product security. Understanding the different types of sealing machines available in the market is essential for businesses looking to streamline their packaging processes and maintain the integrity of their products. In this comprehensive guide, we will explore the definition of sealing machines, the benefits of using them, and delve into the specifics of the most common types of sealing machines used across industries.

13 Types of Sealing Machine

The following are different types of sealing machines will be introduced in this article:

1. Heat sealing machines

2. Plastic sealing machine

3. Vacuum sealing machines

4. Continuous band sealers

5. Impulse sealers

6. Can sealing machines

7. Cup sealing machines

8. Induction sealers

9. Food tray sealing machines

10. Hot bar sealers

11. Sleeve sealers

12. Tube sealing machines

13. Automatic vs. manual sealing machines

What Is a Sealing Machine?

A sealing machine is a device that is used to seal packaging materials, such as bags, pouches, containers, and cups, to protect the contents from external elements, extend shelf life, and prevent tampering. These machines use various methods to create a secure seal, such as heat sealing, vacuum sealing, continuous band sealing, impulse sealing, can sealing, cup sealing, induction sealing, food tray sealing, hot bar sealing, sleeve sealing, and tube sealing.

Benefits of Using Sealing Machines

Increase Product Freshness and Shelf Life

Sealing machines for packaging help to preserve the freshness of products by creating an airtight seal that prevents oxygen and moisture from entering the packaging. This is particularly important for perishable goods, such as food items and pharmaceutical products, as it extends their shelf life and reduces the risk of spoilage.

Improve Packaging Appearance and Quality

Sealing machines create a professional and uniform seal that enhances the overall appearance of the packaging. By ensuring that the contents are securely sealed, these machines also prevent leaks, spills, and contamination, which can compromise the quality of the product.

Enhance Product Security and Tamper-Evident Features

Sealing machines play a crucial role in product security by providing tamper-evident features that indicate if the packaging has been opened or tampered with. This is especially important for industries that deal with sensitive or high-value products, such as pharmaceuticals and electronics, where consumer safety is paramount.

#1: Heat Sealing Machines

Heat sealing machines use heat to melt the packaging material and create a strong seal. These machines are commonly used for sealing bags, pouches, and containers made of plastic or other heat-sealable materials. The heat sealing process involves applying heat and pressure to the packaging material to bond it together and form a tight seal.

Heat sealing machines are versatile and can seal a wide range of packaging materials, including polyethylene, polypropylene, and laminated films. They are also efficient and cost-effective, making them ideal for high-volume production environments. Additionally, heat sealing machines produce strong and secure seals that are resistant to tampering and ensure the integrity of the product inside.

#2: Plastic Sealing Machine

A plastic sealing machine is a device used to seal items in plastic packaging. It is commonly used in industries like food packaging, pharmaceutical, and electronics for sealing various products to protect them from external elements. Plastic sealing machines seal plastic packaging by using heat to melt the edges together, creating a secure barrier around the product to prevent contamination or tampering.

Plastic sealing machines offer advantages such as increased security by providing a tamper-evident barrier, protection from dust and moisture to extend shelf life, efficiency in quickly sealing high volumes of products, and cost-effectiveness by saving on packaging materials and labor costs.

#3: Vacuum Sealing Machines

Vacuum sealing machines remove air from the packaging before sealing it, creating a vacuum-sealed environment that helps to preserve the freshness and quality of the contents. These machines are commonly used for packaging perishable foods, such as meats, cheeses, and vegetables, as well as for storing sensitive items, such as electronics or medical supplies.

Vacuum sealing machines help to extend the shelf life of products by removing oxygen from the packaging, which slows down the oxidation process and reduces the growth of bacteria and mold. They also help to preserve the flavor, texture, and nutritional value of the contents, making them ideal for food items that need to be stored for extended periods.

#4: Continuous Band Sealers

Continuous band sealers are used to seal bags and pouches continuously, allowing for fast and efficient packaging of products. These machines use a heated sealing element and conveyor belt to create airtight seals along the length of the packaging material, making them suitable for high-volume production environments.

Continuous band sealers are versatile and can seal a wide range of packaging materials, including polyethylene, polypropylene, and foil. They are also highly efficient, with adjustable speed and temperature settings that allow for precise control over the sealing process. Additionally, continuous band sealers produce consistent and reliable seals that help to maintain the quality and integrity of the packaged products.

#5: Impulse Sealers

Impulse sealers use a combination of heat and pressure to create a seal by quickly melting the packaging material at the point of contact. These machines are commonly used for sealing bags, pouches, and tubes made of thermoplastic materials, such as polyethylene and polypropylene.

Impulse sealers are easy to operate and require minimal setup, making them ideal for small businesses and low-volume packaging operations. They are also compact and portable, making them versatile for various packaging needs. Additionally, impulse sealers produce strong and durable seals that are resistant to leaks and tears, ensuring the contents remain safe and secure during storage and transportation.

#6: Can Sealing Machines

Can sealing machines are specifically designed to seal metal cans and containers, preserving the freshness and quality of the contents inside. These machines use a combination of heat and pressure to create a hermetic seal that is airtight and tamper-proof.

Can sealing machines are highly durable and reliable, capable of sealing a wide range of can sizes and shapes with precision and efficiency. They are also versatile, with adjustable settings that allow for customization of the sealing process to suit different types of products. Additionally, can sealing machines help to protect the contents from external contaminants and maintain their integrity throughout the distribution and storage process.

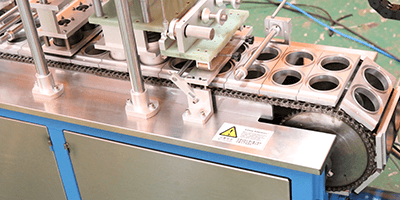

#7: Cup Sealing Machines

Cup sealing machines are designed to seal cups and containers with pre-formed lids, such as plastic, paper, or aluminum foil lids. These machines create a secure seal that prevents leaks, spills, and contamination, making them ideal for packaging beverages, desserts, and other liquid or semi-liquid products.

Cup sealer sealing machine are fast and efficient, capable of sealing multiple cups in a matter of seconds, making them ideal for high-volume production environments. They are also versatile, with adjustable settings that allow for customization of the sealing process to accommodate different cup sizes and materials. Additionally, cup sealing machines help to improve the presentation and quality of the packaged products, enhancing the overall customer experience.

#8: Induction Sealers

Induction sealers use electromagnetic induction to create a hermetic seal on containers with a foil liner. These machines generate an electromagnetic field that heats the foil liner, creating a bond with the container’s lip and forming a secure seal that is tamper-evident and leak-proof.

Induction sealers are highly efficient and produce consistent seals that are resistant to tampering and contamination. They are also versatile, capable of sealing a wide range of container sizes and materials, including plastic, glass, and metal. Additionally, induction sealers help to improve product integrity and safety by providing a secure seal that protects the contents from external elements.

#9: Food Tray Sealing Machine

Food tray sealing machines are used to seal trays and containers with a film or lid, creating a secure barrier that protects the contents from contamination and maintains their freshness and quality. These machines are commonly used in the food industry for packaging ready-to-eat meals, fruits, vegetables, and other perishable products.

Food tray sealing machines help to extend the shelf life of products by creating an airtight seal that preserves freshness and prevents spoilage. They are also versatile, with customizable settings that allow for different tray sizes and materials to be sealed efficiently. Additionally, food tray sealing machines help to improve food safety by providing a tamper-evident seal that protects the contents during storage and transport.

#10: Hot Bar Sealers

Hot bar sealers use heated bars to create a seal by melting the packaging material and bonding it together. These machines are commonly used for sealing bags, pouches, and tubes made of thermoplastic materials, such as polyethylene, polypropylene, and laminated films.

Hot bar sealers are efficient and produce strong seals that are resistant to tampering and leaks. They are also versatile, with adjustable temperature settings that allow for precise control over the sealing process. Additionally, hot bar sealers are cost-effective and easy to maintain, making them ideal for businesses looking to streamline their packaging operations and improve product quality.

#11: Sleeve Sealers

Sleeve sealers are used to seal sleeves and bands around containers, such as bottles, jars, and cans, creating a secure and tamper-evident seal that enhances the appearance and safety of the product. These machines use heat and pressure to shrink the sleeve or band around the container, creating a tight and protective seal.

Sleeve sealers are versatile and can be used with a wide range of container sizes and shapes, making them ideal for packaging various products. They are also efficient, with fast sealing speeds that ensure quick and effective packaging. Additionally, sleeve sealers help to improve product visibility and branding by providing a customized and professional packaging solution.

#12: Tube Sealing Machines

Tube sealing machines are designed to seal tubes and containers with a plastic or aluminum tube, creating a secure and leak-proof seal that protects the contents from external elements. These machines are commonly used in the cosmetics, pharmaceutical, and personal care industries for packaging creams, ointments, gels, and other semi-solid products.

Tube plastic sealing machine are versatile and can seal a wide range of tube sizes and materials, including plastic and aluminum. They are also efficient, with adjustable settings that allow for customization of the sealing process to suit different product requirements. Additionally, tube sealing machines help to improve product integrity and safety by providing a tamper-evident seal that protects the contents from contamination and ensures consumer satisfaction.

#13: Automatic vs. Manual Sealing Machines

Automatic and manual sealing machines are the common choices when selecting from the different types of sealing machines. The following are the pros and cons of each type.

Pros and Cons of Automatic Sealing Machines

Automatic sealing machines are fully automated and require minimal human intervention, making them ideal for high-volume production environments that demand speed and efficiency. These machines are equipped with sensors, timers, and controls that automate the sealing process and ensure consistent and reliable results.

Pros

1. Increased productivity and efficiency

2. Consistent and reliable sealing quality

3. Reduced labor costs and human error

Cons

1. Higher initial investment

2. Limited flexibility and customization options

3. Requires regular maintenance and technical support

Pros and Cons of Manual Sealing Machines

Manual sealing machines are operated by hand and require manual intervention to seal the packaging. These machines are suitable for small businesses, low-volume production environments, and products that require a personalized or customized sealing process.

Pros

1. Lower initial investment

2. Greater flexibility and customization options

3. Easy to operate and maintain

Cons

1. Slower sealing speeds

2. Inconsistent sealing quality

3. Higher labor costs and potential for human error

Factors to Consider When Choosing a Sealing Machine

Production Volume and Speed Requirements

The production volume and speed requirements of your business will determine the type of sealing machine that is suitable for your needs. High-volume production environments may require automatic sealing machines with fast sealing speeds, while low-volume operations may opt for manual sealing machines that offer greater flexibility and customization options.

Packaging Material and Product Compatibility

The type of packaging material and product you intend to seal will influence the choice of sealing machine. Different machines are designed to work with specific materials, such as plastic, paper, foil, or glass, and may not be compatible with all types of products. It is essential to consider the compatibility of the packaging material and product with the sealing machine to ensure a secure and efficient sealing process.

Budget Constraints and Cost Considerations

Budget constraints and cost considerations are crucial factors to consider when choosing a sealing machine for your business. Automatic sealing machines may require a higher initial investment but offer long-term cost savings in terms of productivity, efficiency, and reduced labor costs. Manual sealing machines are more affordable upfront but may incur higher labor costs and lower efficiency in the long run.

Industry Applications of Sealing Machines

Food and Beverage Industry

Sealing machines are widely used in the food and beverage industry for packaging a variety of products, such as snacks, dairy products, beverages, and baked goods. These machines help to maintain the freshness, quality, and safety of food items by creating a secure and tamper-evident seal that protects the contents from contamination and spoilage.

Pharmaceutical and Medical Industry

Sealing machines play a critical role in the pharmaceutical and medical industry by packaging medications, tablets, capsules, and medical devices in a safe and hygienic manner. These machines help to ensure the integrity and efficacy of the products by creating a tamper-proof seal that protects them from external elements and maintains their quality throughout the distribution chain.

Cosmetics and Personal Care Industry

Sealing machines are essential in the cosmetics and personal care industry for packaging creams, lotions, serums, and other beauty products. These machines help to protect the contents from air, light, and moisture by creating a tight and secure seal that preserves the product’s stability and enhances its shelf life. Additionally, sealing machines help to improve product branding and customer satisfaction by providing a professional and attractive packaging solution.

Conclusion

Sealing machines are indispensable tools in various industries for preserving product freshness, improving packaging quality, and enhancing product security. By understanding the different types of sealing machines available and their benefits, businesses can choose the right machine for their specific needs and requirements. Whether you are packaging food, pharmaceuticals, cosmetics, or other products, investing in a quality sealing machine can streamline your packaging process and ensure the integrity and safety of your products.