CHLB supplies professional packaging machines for industries around the globe. The vertical packaging machine, or vertical form fill seal machine(VFFS) is one of the most popular on our list. Based on the products you have to package, the working conditions, and the packaging film you are using, we can tailor a perfect solution.

It seems we can't find what you're looking for.

Our VFFS machines efficiently create specialty bag styles and perform at high speed for maximum throughput. A VFFS machine transports packaging films and prepared products vertically, which saves your plant area expenses. Features of our VFFS Machine are as follows:

We offer a series of quality multi-head weigher and branded servo motors to guarantee that machines calculate more precisely and your final products are packed in stable weight.

You can greatly improve efficiency and save labor cost with the help of our VFFS machines. The machine will run automatically from forming to filling and sealing.

According to the final size and shape of your packaging bags, our engineers are competent for adjusting forming, filling, and sealing devices to deliver you the right machine.

We use SUS 304 stainless steel to meet the requirements of food production, and we provide the user-friendly design to protect your operating staff.

Condiment powder, flour, milk powder, coffee powder and other powders

Whether it's liquid or thick paste and dough, our vertical packaging machines are at your service.

High-precision packaging machine cooperates with multi-head weighing scale.

VFFS(Vertical Form Fill Seal) machines are commonly used in many industries and can be used to pack countless different bags, pouches, and packs.

Both stick bag & drip bags available.

Hardware pellets.

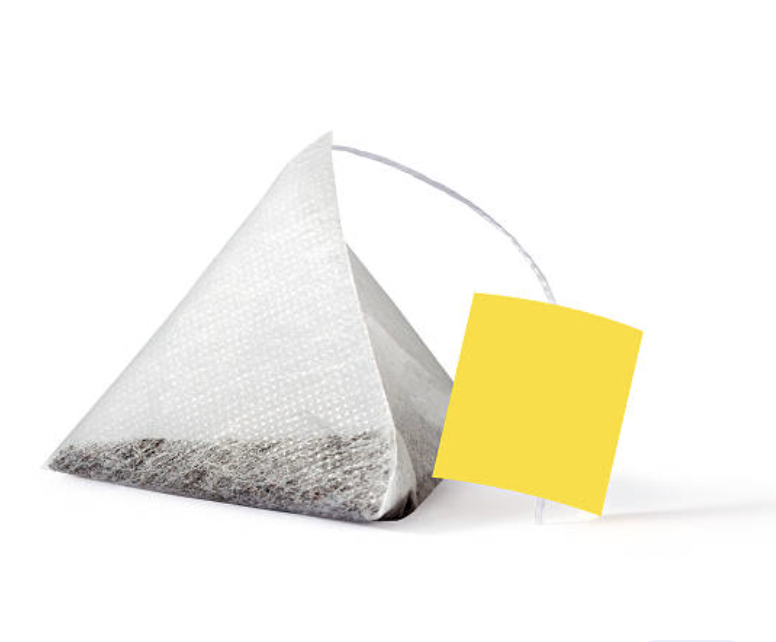

Normal tea bag & pyramid tea bag.

Salt, sugar, pepper, and more.

Beans, rice, nuts, and more.

Cosmetics and body care.

Daily necessities.

Sauce, liquide jelly and more.

Fabric bags and paper handles.

Fabric bags and tags with threads.

Bags with Tags and thread.

Special shapes customizable.

The QC provides a comprehensive overview of quality assurance measures, allowing stakeholders to monitor and manage product quality at every stage.

Raw materials inspection is a vital step in our process. We only adopt premium materials to manufacture high-quality machines.

We guarantee a long service life and great performance by cooperating with famous brands and purchasing:

1.SUS 304 stainless steel is used as a food contact surface

2.Schneider servo drives and servo motors for custom projects

3.Omron solid state relay

4.MCGS operation panels

Rationality of the engineering design makes sure the final machine performance.

By utilizing state-of-the-art CAD software and the rich engineering experience, we efficiently create an accuracy design to meet your needs of specific products, packaging size, and materials.

For the precise assembly and the stable operation of machines, we strictly control the metal processing, including cutting, milling, lathing, welding, and grinding.

Experienced workers and advanced processing equipment deliver clean and smooth appearance as well.

High-performance machines are guaranteed not only by quality materials and precise components but also by well-handled details.

Our technicians keep every component and wire in consistency with the design specification to make sure that the machine will run safely and efficiently.

We will adjust the details to eliminate possible errors and safety risks before delivery by testing:

1.Appearance

2.Accuracy of specifications and dimensions

3.Compatibility

4.Operation for packaging samples without empty bags and chopping products

5.Electronic components

Sourcing bag packaging machines? You will get a free quote or get more details about the solution from our experienced experts.

To receive the optimal free package solution tailored to your needs, kindly complete and submit the form below.