In the manufacturing and logistics world, “packing machines” and “packaging machines” are often used as if they mean the same thing. But they don’t. While both belong to the same automation family, they serve different purposes in your production line. Understanding this difference helps you improve efficiency, control costs, and maintain product quality.

Let’s take a closer look at what they do, how they differ, and how to choose the right equipment for your business.

What Are Packing and Packaging Machines?

A packing machine focuses on product containment and protection. It ensures each item is securely filled, sealed, or boxed before shipment or storage. In many factories, packing machines handle operations such as weighing, bagging, sealing, or labeling. For instance, a powder filling machine measures and fills each packet with a precise weight. A carton sealing machine closes boxes firmly to prevent contamination or leakage. The purpose is to make sure that products remain safe, stable, and ready for logistics handling.

A packaging machine deals with the outer layer that defines how a product is presented to the market. It gives the product its final commercial appearance and often integrates printing, film wrapping, or carton forming. In food and consumer goods industries, packaging machines print barcodes, apply brand graphics, and wrap items in retail-ready materials. The goal is not only to maintain quality but also to meet marketing, labeling, and compliance standards.

Key Differences Between Packing and Packaging Machines

1. Main Function and Role

Packing Machines

• Focused on grouping, sealing, and preparing finished goods for shipment or storage. They organize products so they are easy to move and protect them from damage.

• Often work with boxes or bags, keeping items stable and ready for transport.

Packaging Machines

• Focused on preserving and presenting individual products. They fill, seal, and label items to maintain freshness and appearance.

• Ensure products are ready for retail and market display, not just for storage.

2. Position in the Production Line

Packing Machines

• Located at the very end of the production line. They operate after all primary and secondary packaging steps are complete.

• Arrange already-packaged goods for storage, palletizing, or shipping.

Packaging Machines

• Positioned closer to the manufacturing process. They handle semi-finished products and turn them into ready-to-sell packages.

• Seal pouches, fill bottles, or wrap small boxes before the packing stage.

3. Technical Differences

Packing Machines

• Focused on counting, sorting, and grouping products before final boxing or bagging. For example, they can automatically count items, arrange them neatly, and feed them into containers.

• Often feature auto cartoning, bagging, and sealing systems that improve packing speed and consistency, especially for products like snacks, small parts, or bottles.

Packaging Machines

• Offer a more integrated technology approach. They may combine weighing, filling, sealing, labeling, and inspection modules in a single line.

• Designed to link with other automation systems like filling or labeling lines, enabling a continuous and streamlined workflow.

4. Materials and Handling

Packing Machines

• Handle shipping materials such as cardboard boxes, shrink film, and plastic straps. These materials focus on strength and stability during transport.

• Keep large volumes secure, stacked properly, and easy to move.

Packaging Machines

• Handle product-contact materials like films, foils, pouches, and printed cartons. They focus on sealing quality and appearance.

• Ensure products remain fresh, clean, and visually appealing for consumers.

5. Output and Speed

Packing Machines

• Designed for bulk handling. They typically process 20 to 30 boxes per minute, depending on automation.

• Focus on stability and accurate loading rather than maximum unit speed.

Packaging Machines

• Designed for unit-level production. Some machines can fill or seal more than 100 packages per minute.

• Speed and precision directly affect efficiency, material usage, and product quality.

6. Business Impact

Packing Machines

• Reduce labor costs, prevent product damage, and improve logistics efficiency.

• Support large-volume orders and long-distance shipping, keeping supply consistent.

Packaging Machines

• Influence brand perception through quality sealing, labeling, and presentation.

• Enhance consumer trust, retail compliance, and long-term brand reputation.

Summary Table: Packing vs Packaging Machines

| Aspect | Packing Machines | Packaging Machines |

| Main Function | Grouping, sealing, preparing for shipment | Preserving, presenting, retail-ready packaging |

| Production Stage | End of line, after primary and secondary packaging | Closer to production, transforms semi-finished goods |

| Technology | Counting, sorting, auto cartoning, bagging, sealing | Integrated modules: weighing, filling, sealing, labeling, inspection |

| Materials | Cardboard, shrink film, straps, boxes | Films, foils, pouches, printed cartons |

| Output & Speed | Bulk handling, 20–30 boxes per minute, focus on stability | Unit-level, 80–120 units per minute, focus on precision |

| Focus | Logistics, product protection during transit | Market readiness, freshness, appearance, brand perception |

| Consumer Interaction | Indirect | Direct |

| Business Impact | Labor reduction, damage prevention, shipping efficiency | Brand enhancement, retail compliance, consumer trust |

Types and Applications of Packing and Packaging Machines

Common Types of Packing Machines

Clay/Plasticine Packing Machine

• Definition: A machine designed to handle soft, malleable products such as clay, plasticine, or similar substances.

• Features: Automatically fills pre-made bags or containers with soft materials, ensuring uniformity and minimal wastage.

• Applications: Ideal for packing clay, plasticine, modeling compounds, and other similar soft goods.

Cartoning Machine

• Definition: A machine that forms, loads, and seals cartons or boxes, designed for high-speed bulk packing.

• Features: Adjustable carton sizes, automatic folding, and sealing mechanisms, often integrated with labeling systems.

• Applications: Used for packing bottled beverages, snack foods, cosmetics, and other retail-ready products in cartons.

Case Packers

• Definition: Machines designed to automatically load products into outer packaging, typically corrugated cases or boxes.

• Features: Handles various product sizes and configurations with precise counting and alignment systems.

• Applications: Ideal for packing canned goods, bottled products, small parts, or bulk items into cases for transport.

Bagging Machines

• Definition: Machines that automatically fill pre-made bags with a variety of products, from granular items to bulk liquids or powders.

• Features: Adjustable filling systems and integrated sealing to ensure consistent bag weight and secure seals.

• Applications: Used for packing grains, snacks, candies, fertilizers, pet food, and other bulk products into bags.

Common Types of Packaging Machines

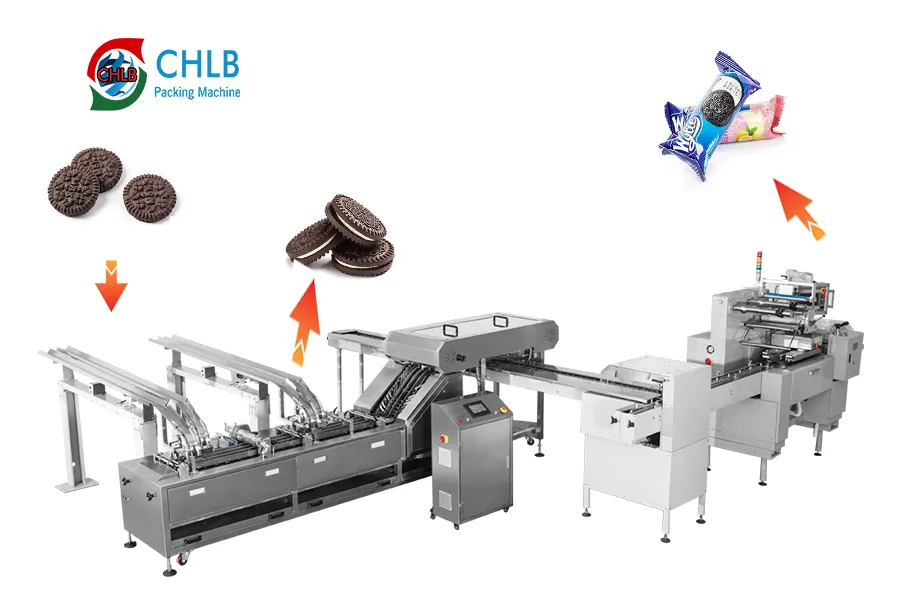

Horizontal Flow Packing Machine

• Definition: A machine that wraps products in a continuous horizontal motion, forming sealed packs.

• Features: Handles products of various shapes and sizes, integrates feeding, sealing, and cutting in one line.

• Applications: Suitable for packing biscuits, candies, chocolate bars, and similar solid products.

Vertical Form Fill Seal Machine (VFFS Machine)

• Definition: A machine that forms bags from a roll of film, fills them with product, and seals them vertically.

• Features: Supports powders, granules, and small solid items; automatic bag forming, filling, and sealing.

• Applications: Ideal for packing rice, sugar, coffee, snacks, and small hardware parts.

Cling Film Packaging Machine

• Definition: A machine that wraps products with stretchable cling film to secure and protect them.

• Features: Provides tight wrapping, reduces the movement of products, and can handle irregular shapes.

• Applications: Suitable for trays of fresh food, produce, bakery items, and boxed products.

Thermoforming Packaging Machine

• Definition: A machine that heats a plastic sheet to form a cavity, fills it with product, and seals it with a top film.

• Features: High precision forming and sealing, suitable for rigid or semi-rigid packaging.

• Applications: Commonly used for fresh meat, ready-to-eat meals, dairy products, and blister packs.

How to Choose the Right Machine for Your Business

Define Your Product and Packaging Requirements

Start by identifying what your product truly needs: primary packaging (for sealing and protecting individual items) or secondary packing (for grouping and shipping).

- Packaging machines, such as horizontal flow wrappers or vertical form fill seal (VFFS) systems, are ideal for handling single products like snacks, coffee, or liquids that need tight sealing or aesthetic presentation.

- Packing machines, on the other hand, are better for boxed, bagged, or bulk products that are already packaged and need to be grouped or palletized for transport.

Your product’s shape, fragility, and texture also influence machine selection. For example, biscuits or soaps fit well with flow packing machines, while rice or granules are better suited for VFFS systems.

Evaluate Production Capacity and Automation Level

Production scale is one of the strongest indicators of which type of machine you need.

- For high-speed manufacturing lines, an automatic packaging system, such as a thermoforming or flow wrapping machine, ensures continuous and stable operation.

- For warehouse or distribution operations, semi-automatic packing lines may be more cost-effective and flexible.

Modern industrial packaging equipment can integrate with weighing, labeling, and coding systems, allowing full-line automation that minimizes labor and maintains consistent output.

Check Material Compatibility

The choice of material also defines the type of machine required.

- Packaging machines handle films like PE, PET, or multilayer laminates used for sealing, vacuuming, or branding.

- Packing machines typically deal with materials for boxes, shrink wraps, or stretch films used in logistics.

For instance, cling film packaging machines require highly stretchable film, while VFFS machines need roll films suitable for heat sealing. Ensuring proper material compatibility guarantees smooth operation, strong seals, and product safety.

Review Maintenance, Support, and Spare Parts Availability

Whether you choose a packing or packaging machine, reliable after-sales service is essential. Look for suppliers offering operator training, technical assistance, and fast spare-part delivery. High-quality components, such as branded sensors, PLC systems, or electrical modules, improve machine stability and simplify long-term maintenance.

Assess Budget and Return on Investment

Your decision should go beyond initial cost. A low-priced machine may result in more downtime or higher material waste, while a premium automatic system could deliver faster ROI through higher efficiency and accuracy.

When comparing options, calculate your total cost of ownership, including maintenance, labor, and energy consumption. For expanding businesses, choose a system that allows future upgrades or customization to scale with your growth.

Final Thoughts

Packing machines and packaging machines each play unique roles in the production chain, from protecting individual items to preparing finished goods for shipping. When you match the machine to the product, the materials, and your production goals, you not only reduce waste and labor but also create a smoother, more reliable operation.

If you are still deciding which solution fits your business best, CHLB is here to help. With years of experience in industrial automation and customized packing and packaging systems, CHLB supports you from early project evaluation to installation, training, and long-term maintenance. You do not need to figure everything out alone, and we will guide you through every detail to ensure you invest with confidence.

Ready to upgrade efficiency and streamline your production line?

Reach out to CHLB, and let’s find the machines that truly work for your business.

FAQs

1. How does a thermoforming packaging machine work?

It heats and shapes plastic film into custom trays or cavities, then fills and seals the product. This creates strong, airtight packaging commonly used for food and medical items.

2. What are the different types of flow packaging machines?

The two main types are horizontal flow wrappers and vertical flow wrappers. Horizontal models suit solid items, while vertical models handle powders or granular products.

3. What is a clay packing machine?

It weighs, fills, and packs clay blocks or plasticine into bags or wraps. The machine ensures consistent weight and tight, clean packaging.

4. How do you use a plasticine packing machine?

Adjust the weight and speed settings based on your product, and the machine automatically portions and wraps the clay. It keeps the packaging uniform and neat.

5. What is a packaging machine?

Packaging machinery is used throughout all packaging operations, involving primary packages to distribution packs. This includes many packaging processes: fabrication, cleaning, filling, sealing, combining, labeling, overwrapping, and palletizing.