Wrapping food by hand can be messy, slow, and inconsistent. Enter the cling film wrapping machine, a simple device that turns this chore into a fast, precise, and hygienic process. From fresh sandwiches to fruits, baked goods, and more, it keeps your products safe, fresh, and ready to sell.

In this guide, you’ll discover how to use a cling film wrapping machine like a pro, understand its key features, and learn tips to speed up your food packaging while cutting waste and labor. Whether you run a café, bakery, or supermarket, this machine can transform the way you handle packaging.

Step 1: Prepare the Machine and Load Cling Film

Before you start wrapping food, preparing the machine is the first and most critical step. Skipping this step can cause poor seals, uneven wrapping, or even damage the machine, which you definitely want to avoid.

Check Machine Condition

Always begin by inspecting the machine for visible damage, loose screws, or worn parts. Check film rollers, heating elements, and the control panel. Even small dust on the sealing bar affects wrap quality. If your machine has automatic tension adjustment, ensure sensors are responsive. Over 30% of wrapping issues stem from poor maintenance, so checking your equipment saves problems later.

Install the Cling Film Roll

Installing the cling film roll correctly is essential. Ensure the film unwinds smoothly without resistance. For a standard 30 cm roll, align the edge straight into the sealing area. Incorrect installation can cause wrinkles or partial seals, compromising food safety. Use high-quality films with consistent thickness (8–12 microns). Thicker films provide stronger seals but may need slight temperature adjustment.

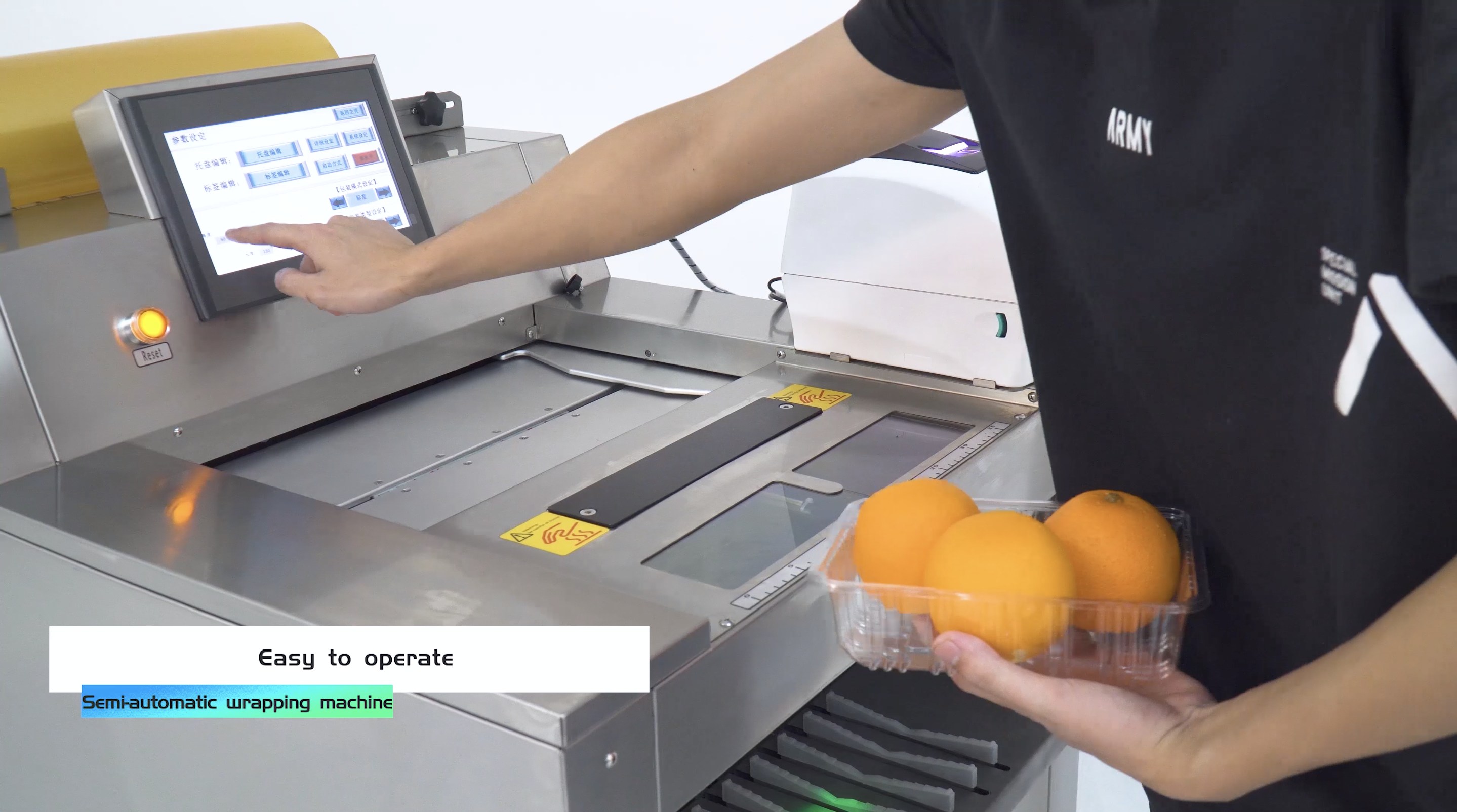

Adjust Machine Settings

Modern wrapping machines offer multiple adjustable settings. You should check and set:

- Sealing temperature: Higher for thick or moist foods, lower for delicate items.

- Wrap speed: Faster speeds increase productivity but may reduce wrap tightness.

- Film tension: Controls how snugly the film adheres to the product.

For example, when you wrap fresh meat or cheese, a slightly higher temperature (about 120–130°C) ensures a strong seal. For delicate pastries, keep the temperature around 90–100°C to prevent melting or deformation. Adjusting these parameters properly reduces product waste and ensures consistent quality for your production line.

Step 2: Load Food Products and Start Wrapping

Once your machine is prepared, it’s time to load the food. Proper loading ensures even wrapping and avoids damage to the items you are packaging.

Select Suitable Food Items

Not all foods are ideal for cling film wrapping. You should focus on:

- Pre-cut fruits and vegetables

- Sandwiches and ready-to-eat meals

- Meat, fish, and cheese

- Bakery products

Foods with high moisture content or irregular shapes may require specific settings or additional trays to maintain shape. For instance, if you wrap soft cheese, you might need a light tray or support sheet to avoid crushing it during wrapping.

Arrange Food Properly

Arrange your items neatly on the conveyor or wrapping tray. Avoid overlapping items, as this can cause uneven sealing or trapped air. Space each item 2–3 cm apart to allow the film to conform to its shape. When packaging multiple items, stack in uniform layers for stability. Correct arrangement helps you prevent seal failures in your production line.

Start the Wrapping Process

With the food arranged, start your machine. Automatic machines feed, wrap, and seal items in a single cycle. Monitor the first few cycles to ensure alignment and proper sealing. Adjust film tension or speed if you notice wrinkles or loose edges. Check every 50–100 items to maintain consistent quality throughout your production.

Step 3: Inspect Wrapped Food and Ensure Quality

Check Seal Integrity

Examine the seal line closely. A strong, uniform seal prevents air, moisture, or contaminants from entering. Poor seals often appear wrinkled, broken, or incomplete. Press gently along the edge to confirm adhesion. Use machine adjustments for heat and pressure if needed. Acceptable seals should withstand 2–3 kg of gentle pull.

Inspect Film Appearance

Ensure the film is smooth, transparent, and free of bubbles or tears. Wrinkles or trapped air may indicate tension or alignment issues. Adjust feed speed or tension if needed. Using high-quality films reduces defects. Your packaged items should look as appealing as they are fresh.

Store Wrapped Products Safely

Transfer wrapped products to proper storage immediately. Refrigerate perishables (0–4°C) and store shelf-stable items at room temperature, avoiding direct sunlight or high humidity. Proper storage maintains seal integrity and prolongs shelf life. Rotate stock on a first-in, first-out basis to keep food fresh.

Step 4: Clean and Maintain the Machine

Clean the Machine Thoroughly

After each production cycle, clean your machine to prevent food residues from sticking to rollers or sealing bars. Use a soft cloth with mild detergent and avoid abrasive materials that can scratch components. If you handle raw meat or fish, consider sanitizing with food-safe solutions to prevent bacterial growth. Regular cleaning also extends the life of sensors and electronic controls.

Lubricate and Check Parts

Lubrication is critical for moving parts such as conveyor belts, rollers, and gears. Use food-grade lubricants to avoid contamination. Check belts and rollers for signs of wear, and replace them if necessary. A well-lubricated machine runs smoother, produces more consistent wrapping, and reduces the risk of breakdowns for you.

Schedule Regular Maintenance

Besides daily cleaning, schedule preventive maintenance at least every 3–6 months, depending on how often you use the machine. This includes checking electrical components, testing sensors, and inspecting heating elements.

Many manufacturers recommend professional servicing once a year to maintain peak performance. Machines receiving regular preventive maintenance have a 25–30% lower downtime rate compared to those without scheduled checks. Following this routine will save you time and money in the long run.

Final Thoughts

Cling film wrapping machines make food packaging faster, cleaner, and more consistent. By automating the process, you save time, reduce waste, and ensure every product looks fresh and appealing. Whether you run a bakery, deli, or supermarket, these machines turn a routine task into a smooth, professional operation.

If you want reliable performance and smart design, the best wrapping machine manufacturers like CHLB Packaging Machine Co., Ltd., offer a range of automatic food wrapping machines that deliver quality and efficiency.

👉Learn more about our solutions on the CHLB Packaging website, and find out how a single machine can transform your food packaging workflow.