1 분마다 생산 라인이 유휴 상태가됩니다. 모든 불완전한 인감은 당신의 명성을 위험에 빠뜨립니다. 제조 중, 잘못된 수직 형태의 채우기 씰 선택 (VFFS) 기계는 단순한 감독 일뿐 만 아니라 비즈니스 크리티컬 오류입니다.

고성능 VFFS 기계 생산을 묘사하십시오 300 분당 가방, 액체를 원활하게 포장합니다, 분말, 또는 완벽한 일관성을 가진 곡물. 올바른 기계는 생산 라인의 심장 박동이됩니다, 귀하의 비즈니스와 함께 성장하도록 구축되었습니다.

모든 VFF 시스템이 동일하게 생성되는 것은 아닙니다. 신뢰할 수있는 결과와 유지 보수의 차이점은 건축 품질로 이어집니다., 재료, 요구 사항과의 호환성. 이 안내서는 업계 리더를 값 비싼 실수와 분리시키는 것을 보여줍니다..

수직 형태의 채우기 씰 기계는 무엇입니까??

VFFS 개요

에이 수직형 충전 밀봉 기계, 또는 VFFS 기계, 포장 장비의 유형입니다. 그것은 만드는 데 도움이됩니다, 채우다, 가방을 자동으로 밀봉합니다. 당신은 영화 롤을 기계에 넣는 것으로 시작합니다.. 기계는 필름을 튜브로 형성합니다. 그런 다음 튜브를 제품으로 채 웁니다. 이후, 완성 된 가방을 만들기 위해 튜브를 밀봉합니다. 이것을 수직 형태 충전 씰 머신의 작동 원리라고합니다.. 많은 것에 VFFS 기계를 사용할 수 있습니다. 분말에 대해 작동합니다, 액체, 간식, 그리고 냉동 식품.

VFFS 기계 많은 모델과 크기로 제공됩니다. 각 모델에는 다양한 산업에 특수 기능이 있습니다. 아래 표에는 몇 가지 일반적인 VFFS 머신 모델이 나와 있습니다. 기술적 인 세부 사항과 사용할 수있는 곳을 보여줍니다.:

제품 시리즈 비교

매개 변수 | PA 시리즈 (가루) | 오후 시리즈 (작은 낟알) | PP 시리즈 (액체) | PV 시리즈 (부피) |

|---|---|---|---|---|

모델 | ||||

애플리케이션 | 파우더 제품 | 과립 제품 | 액체 제품 | 다양한 벌크 제품 |

계량 장치 | Augs 복용량 | 멀티 헤드 계량기 | 액체 펌프 | 부피 컵 필러 |

기술 사양 (모든 시리즈에 대해 동일합니다)

사양 | 420 모델 | 520 모델 | 680 모델 |

|---|---|---|---|

롤 필름의 최대 너비 | 420mm | 520mm | 720mm |

최대 백 너비 | 200mm | 250mm | 350mm |

최대 백 길이 | 300mm | 400mm | 480mm |

포장 속도 | 5-60 부대/분 (단일 가방 중량에 따르면) | 5-60 부대/분 (단일 가방 중량에 따르면) | 5-60 부대/분 (단일 가방 중량에 따르면) |

측정 범위 | 150-1200밀리리터 | 3000밀리리터 | 6000밀리리터 |

포장재 | 복합 필름 (UP/CPP, UP/PE, 애완 동물/PE, NY/PE 등) 또는 순수한 PE 필름 | 복합 필름 (UP/CPP, UP/PE, 애완 동물/PE, NY/PE 등) 또는 순수한 PE 필름 | 복합 필름 (UP/CPP, UP/PE, 애완 동물/PE, NY/PE 등) 또는 순수한 PE 필름 |

공기 소비 | ≥0.65MPA | ≥0.65MPA | ≥0.65MPA |

전력 전압 | 220V/380V, 50Hz/60Hz, 1 위상/3 단계 | 220V/380V, 50Hz/60Hz, 1 위상/3 단계 | 220V/380V, 50Hz/60Hz, 1 위상/3 단계 |

힘 | 2KW | 2.5KW | 3.5KW |

순 중량 | 550KGS | 650KGS | 720KGS |

내구성이 중요한 이유

강력한 수직 형태의 채우기 씰 머신은 작업을 계속합니다.. 당신은 하루 종일 채우고 밀봉 할 수있는 기계를 원합니다.. 새로운 VFFS 기계는 스테인리스 스틸과 같은 거친 재료를 사용합니다. 또한 쉽게 청소 제어 기능이 있습니다. 이런 것들은 빠르게 청소하고 수리를 덜 멈추는 데 도움이됩니다..

팁: 초음파 밀봉이있는 기계가 강하게 만듭니다, 누출 방지 씰. 이것은 당신의 제품을 안전하게 유지하고 포장이 좋아 보입니다..

오늘날의 VFFS 머신은 스마트 기술을 사용합니다. 많은 사람들이 있습니다 일체 포함, IoT, 그리고 센서 그들이 어떻게 작동하는지 지켜 봅니다. 이러한 기능은 문제를 일찍 찾는 데 도움이됩니다. 이것은 기계가 더 오래 지속된다는 것을 의미합니다. 빠른 VFFS 머신은 최대 채우고 밀봉 할 수 있습니다 40,000 매시간 단위. 이것은 큰 공장이 많은 제품을 만드는 데 도움이됩니다.

내구성있는 수직 형태의 채우기 씰 머신에서 찾아야 할 것

당신은 하루 종일 일하고 당신의 필요를 따라 잡을 수있는 VFF를 원합니다.. 매년 강력한 결과를 제공해야합니다. 권리 VFFS 포장 기계 문제를 피하고 충전 과정을 쉽게 유지하도록 도와줍니다..

빌드 품질

VFFS 머신을 확인할 때 빌드 품질이 매우 중요합니다.. 강력한 프레임과 좋은 빌드는 기계가 몇 시간 동안 작동하는 데 도움이됩니다.. 이런 것들을 찾아야합니다:

견고한 프레임: 중단 프레임은 VFFS 포장 기계가 채워지고 씰이있을 때 안정적으로 유지합니다.. 이것은 흔들리는 것을 멈추고 각 가방을 동일하게 만드는 데 도움이됩니다..

정밀 엔지니어링: 부품이 빡빡하고 좋은 기계가 더 잘 작동합니다. 그들은 낭비가 적고 잼이 적은 가방을 채우고 밀봉합니다..

특허받은 봉인 기술: 일부 VFF Packaging Machinery는 두 단계를 사용하여 백을 밀봉합니다.. 이것은 물개를 더 강하고 안전하게 만듭니다, 따라서 기계가 더 잘 작동합니다.

특수 형성 세트: 종이 기반 필름을 사용하는 경우, 특별 형성 세트는이 영화들이 순조롭게 움직이는 데 도움이됩니다. 이것은 눈물을 멈추고 충전 과정을 안정적으로 유지합니다.

전원 풀기 메커니즘: 이 시스템은 필름을 뒤에서 밀어 넣습니다. 이것은 기계가 채워지고 물개가있을 때 필름이 찢어 질 가능성을 낮추고.

메모: 기계 부품의 필름 슬라이드 방식은 VFFS 포장 기계가 얼마나 잘 작동하는지 변경할 수 있습니다.. 이것을 확인하지 않으면, 기계가 마모되거나 부러 질 수 있습니다. 좋은 엔지니어링은 기계가 잘 작동하는 데 도움이됩니다.

또한 VFF Packaging Machine이 얼마나 오래 지속 될지 생각해야합니다.. 때때로, 새 부품을 추가 할 수 있습니다 “녹색 업그레이드” 오래된 기계에. 이것은 새로운 포장 필름을 사용하는 데 도움이되고 새로운 포장 필름을 구입하지 않고도 기계를 잘 작동시킵니다..

재료 선택

재료 선택은 내구성있는 수직 형태의 채우기 씰 기계에서 찾을 것의 큰 부분입니다.. 올바른 재료는 VFF가 매일 사용 및 청소를 통해 지속되는 데 도움이됩니다.. 다음은 좋은 VFFS 머신에서 볼 수있는 몇 가지 일반적인 재료입니다.:

재료 | 이익 | VFFS 기계의 일반적인 용도 |

|---|---|---|

스테인레스 스틸 | 녹슬거나 부식되지 않습니다. 청소하기 쉽습니다. 강한 화학 물질을 처리합니다. | 프레임, 접촉 부품, 충전 튜브, 밀봉 턱 |

CHLB (크롬 강화 저 베이니트) | 매우 단단하고 빨리 마모되지 않습니다. 많은 스트레스를 처리합니다. | 밀봉 턱, 절단 블레이드 |

양극화 된 알루미늄 | 가볍지 만 강합니다. 녹슬지 않습니다. | 비접촉 기계 부품 |

스테인리스 스틸은 대부분의 VFFS 포장 기계에 가장 적합한 선택입니다., 특히 식품 및 화학 공장에서. It keeps your filling process safe and clean. CHLB parts last longer and help your machine work well even with heavy use. Anodized aluminum makes the machine lighter but still strong.

팁: Ask your supplier about the materials in the filling and sealing spots. These parts get used the most and need the best protection.

Product and Packaging Compatibility

제품 유형

Each product type needs something different. 분말, 과립, 액체, and solids all act in their own way. Gravity helps powders and liquids move into bags easily. This makes filling smooth for these products. But soft foods like chips or candies can break if they fall too fast. You need to use the right filling system for each product. This keeps your packaging process running well.

Some machines have special feeders for sticky or fragile items. Others use augers or pumps for thick liquids and pastes. Food and medicine companies must follow strict hygiene rules. VFFS packaging machines with easy-to-clean parts help meet these rules. Good sealing also helps keep things safe.

팁: Test your product with the VFFS machine before buying. This shows if the machine can pack your product without damage.

포장 재료

The packaging material you pick changes how your VFFS machine works. You can use plastic, metalized foil, 종이, or fabric. Each one has its own good points and problems. Plastic films seal fast and keep out air and water. Metalized foil gives extra protection for things that must stay fresh. Paper and fabric are better for the environment, but may need special sealing.

Material Type | 이익 | Common Uses |

|---|---|---|

플라스틱 | Fast sealing, moisture barrier | 스낵, 분말, 액체 |

Metalized Foil | High barrier, long shelf life | 커피, 향료, 음식 |

종이 | Eco-friendly, printable | Dry foods, 차, 작살 |

Fabric | 통기성, unique appearance | Specialty items, 생산하다 |

More companies want to use packaging that is better for the planet. Recyclable or compostable films are getting popular. These new materials can change how your VFFS machine seals and cuts bags. You might need to change the heat or pressure to get a good seal. Some machines have controls that help with these materials.

메모: It is important to be flexible with packaging. The best VFFS machines let you change materials and bag sizes easily. This helps you keep up with what customers want.

속도와 효율성

Output Rates

When you choose a vffs machine, you want to know how fast it can work. Speed matters in every packaging line. 높은 output rates help you meet big orders and keep your customers happy. Many vffs packaging machines can fill and seal hundreds of bags each minute. Some advanced models reach up to 300 분당 가방. This level of speed can change how you run your business.

You should look at the type of product you want to pack. 분말, 액체, and snacks all move at different speeds through the machine. Lighter products often allow faster packaging. Heavy or sticky products may slow down the process. You can check the machine’s technical sheet for its maximum speed. Always test your product to see the real output rate.

Tool-less Changeover

Tool-less changeover is a key feature in modern packaging machines. You can switch between different bag sizes or packaging materials without using special tools. This saves you time and keeps your line running. Quick changeovers help you stay flexible. You can respond to new orders or packaging trends fast.

Many vffs machines now have easy-to-adjust parts. You can move guides, change forming tubes, or swap sealing jaws by hand. This means less downtime and more efficiency in your daily work.

You spend less time stopping the machine.

You reduce the risk of mistakes during setup.

You keep your packaging quality high.

Maintenance and Spare Parts

유지 보수의 용이성

You want your vertical form fill seal machine to run smoothly every day. Easy maintenance helps you keep your machine in top shape.

Many modern machines have clear labels and color-coded parts. These features help you find what you need fast. Some machines even have built-in cleaning programs. You press a button, and the machine cleans itself. This keeps your packaging area safe and clean.

팁: Check if the machine comes with a maintenance manual. A good manual gives you step-by-step guides and pictures. This helps you fix small problems on your own.

Spare Parts Availability

Spare parts play a big role in keeping your VFFS machine working. You need to know that you can get parts quickly when something wears out. Ask your supplier about their spare parts policy before you buy. Some companies keep common parts in stock and ship them fast.

메모: Always ask for a list of recommended spare parts when you buy your machine. This list helps you plan ahead and avoid long downtimes.

Supplier and After-Sales Support

Reputation

Picking a vertical form fill seal machine means you should check the supplier’s reputation. A good supplier makes you feel safe about your choice. You want a company that helps you if something goes wrong. Trusted suppliers have happy customers and good reviews. They answer your questions fast and fix problems quickly.

Suppliers with a strong reputation help you avoid trouble. They give better support and send spare parts faster.

It is easier to use your warranty with a trusted supplier.

Good suppliers may have offices or partners near you. This means you get help without waiting too long.

Companies with great reputations sell machines that last longer and break less often.

메모: Always see if the supplier has after-sales support close to you. This can save you time and money if you need help.

Training and Service

After-sales support is not just about fixing machines. You also need training and service to keep your VFFS machine working well. Good suppliers teach your team how to use and care for the machine. They might give in-person lessons, online videos, or easy manuals. Training helps your workers avoid mistakes and keeps everyone safe.

Find suppliers who offer training for operators and simple guides.

Some companies can check your machine from far away using remote tools. This helps fix problems fast.

Getting spare parts quickly is important. You do not want your machine to stop for a long time.

Local support means you can fix problems right away.

팁: Ask about the warranty and service plans before you buy. A good service plan protects your money and keeps your machine running for years.

Integration and Footprint

System Compatibility

You want your vertical form fill seal machine to work with your other machines. System compatibility means your new machine can join your current production line. Check if the VFFS machine can connect to your weighing, 충전재, or labeling machines. Some machines use common communication protocols like Ethernet/IP or Modbus. These protocols help your machines share information.

If you want more automation, pick a VFFS machine that works with robotic arms or conveyors. This makes your packaging process faster and easier. You can also link your VFFS machine to data systems. This lets you watch production numbers and find problems early.

팁: Ask your supplier for a list of equipment and software that works with the machine. This helps you avoid spending extra money later.

Here is a simple checklist for system compatibility:

Can the machine connect to your conveyors or feeders?

Does it work with your labeling or printing machines?

Can you link it to your quality control systems?

Does it use common communication protocols?

Floor Space

You need to know how much space your VFFS machine will use. Floor space is important in every factory. Some machines are small and fit in tight spots. Others need more room for film rolls, feeders, or for cleaning.

Measure your space before you buy a machine. Check the machine’s size in the technical sheet. Leave extra space for workers to move and clean. If you want to grow, think about how much space you will need later.

비용과 ROI

Upfront vs. Long-Term Costs

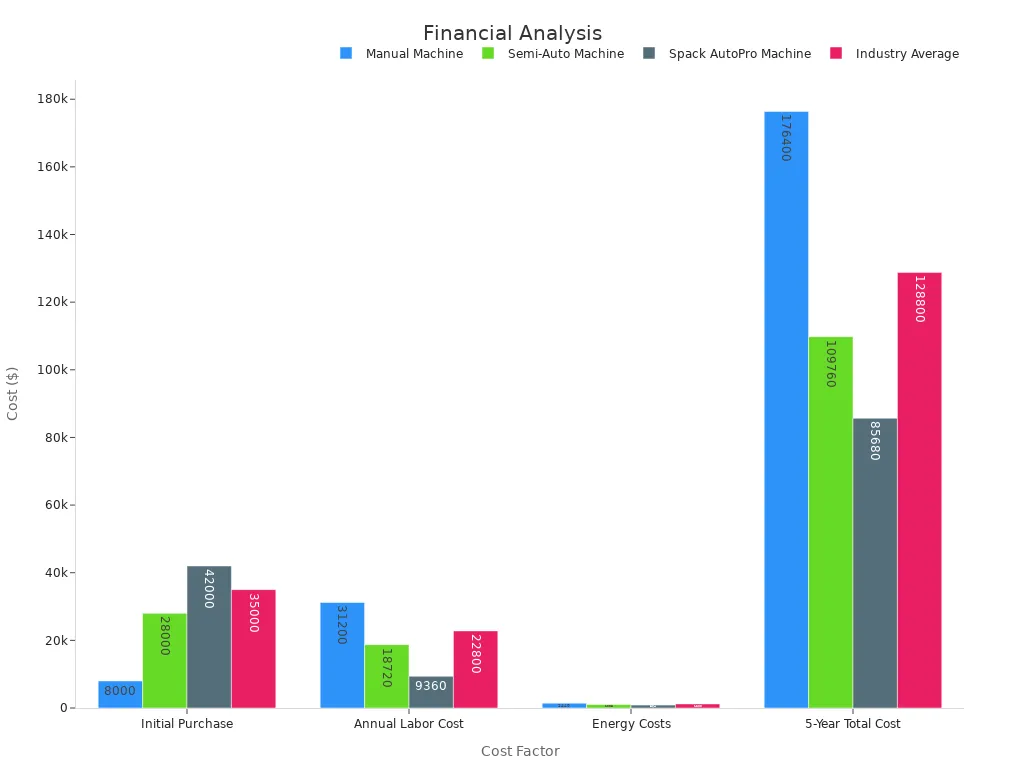

When you buy a vertical form fill seal machine, you need to look beyond the sticker price. The initial cost is only one part of the total investment. You also pay for labor, energy, and material waste over time. These ongoing costs can add up quickly.

You can see that automatic machines cost more at first. 하지만, they save you money on labor and waste. Over five years, the total cost of ownership drops. You get more value from your investment.

팁: Always check the long-term costs before you decide. A higher upfront price can mean bigger savings later.

ROI Assessment

You want to know how fast your investment pays off. Return on investment (ROI) shows how quickly you recover your money. Automatic VFFS machines often give you a faster ROI because they work faster and waste less material.

A real-world example shows this in action. A spice company in Texas bought a VFFS machine for $34,000. They made back their money in just eight months. This happened because the machine packed more bags per hour and used less labor.

You can use ROI to compare machines. Look at how much you save on labor, energy, and waste. The faster you reach payback, the better your investment. Always ask suppliers for real numbers and case studies. This helps you make a smart choice for your business.

Safety and Compliance

Safety Features

It is important to keep workers and products safe when using a vertical form fill seal machine. New VFFS machines have many safety features to protect people and goods. These features help stop accidents and keep packaging running well.

Tamper-evident packaging shows if a bag was opened before the customer gets it. This is very important for 음식, 약, and other products people use.

Automated sealing closes every package tightly. This helps stop leaks and spills.

Barrier films keep out water, 공기, and dirt. Your products stay fresh and safe longer.

Some machines use air pressure or closed spaces to keep out germs and dust.

Quick-release parts and smooth corners make cleaning simple. You can take off parts fast and wash them well. This helps stop bacteria from growing.

팁: Always see if your machine has traceability features. These let you track each package from start to finish. This makes recalls and audits easier.

Regulatory Standards

You must follow strict rules when packing food, 약, or other sensitive items. VFFS machines meet many important standards to help you follow the rules.

Standard or Feature | What It Means for You |

|---|---|

Your machine is safe for food and meets safety laws. | |

Food-Grade Stainless Steel | All parts that touch your product do not rust and are easy to clean. |

Hygienic Design | Smooth edges and Clean-in-Place systems lower the risk of germs. |

HEPA Filtration | Air inside the machine stays clean and keeps products safe. |

Validation Protocols | You can show your cleaning and safety steps work. This helps with audits. |

Many machines also follow world food safety rules and may have extra certifications like EHEDG. These steps help you avoid legal problems and protect your brand. Special film features, like UV protection or anti-static layers, can help you meet special rules for your business.

메모: Following these standards can lower contamination risks by up to 90%. Always ask your supplier for proof of compliance before you buy.

Automatic Vertical Form Fill Seal Machine Options

Automation Benefits

There are many kinds of 수직 형태는 씰 기계를 채우십시오. The main types are automatic and semi-automatic. An automatic vertical form fill seal machine does almost everything by itself. It makes, 채우다, and seals bags with little help from people. Semi-automatic machines need more help from workers. You might have to put in materials or start each step.

Automatic machines work very fast. They can pack hundreds of bags every minute. This speed helps you finish big orders and keep up with what people want. These machines are also more accurate. They measure each product and seal every bag the same way. This means you waste less and make fewer mistakes.

Here is a simple comparison:

특징 | Automatic VFFS | Semi-Automatic VFFS |

|---|---|---|

속도 | 매우 높음 | Medium |

Labor Needed | Low | Medium-High |

정확성 | 높은 | Medium |

가장 좋습니다 | Large batches | Small batches |

팁: If you want to use less labor and pack more bags, pick an automatic vertical form fill seal machine.

유연한 포장

You need your packaging line to be flexible. Different products and customers want different bag shapes and sizes. Automatic vertical form fill seal machines let you change packaging styles quickly. You can pack snacks, 분말, or liquids with the same machine. You just change a few settings or parts.

Some machines can use many packaging materials. You can use plastic, 박, or paper films. This helps you give customers what they want and try new ideas. You can make pillow bags, gusseted bags, or stand-up pouches.

You can pack small or big batches.

You can try new packaging ideas without buying another machine.

You can keep your line working with less stopping.

메모: Flexible packaging choices help your business grow and stay ahead of others.

Buyer’s Guide to VFFS Machines

Evaluation Checklist

You want to pick the best 수직형 충전 밀봉 기계. Use this checklist to help you compare machines:

Check how much you need to pack each day. Make sure the machine can keep up with your work.

Think about what you will pack. Solids, 분말, and liquids may need different machine features.

Measure your space. The machine must fit in your building.

Decide how much money you can spend. Remember to think about both the price now and future costs.

Look at the packaging materials you want to use. Some machines work better with certain films or foils.

Ask about safety features. Look for things like automatic shut-off and ways to stop moisture or mold.

Compare different companies. Pick one with a good name and strong certifications.

Test for problems. Make sure the machine seals bags well and does not rip the film.

Figure out your return on investment. The right machine should help your business grow.

Check if it is easy to fix small problems. You want to fix things like bag misalignment or bad seals fast.

팁: Print this checklist and use it when you shop. It will help you remember what to look for.

Expert Consultation

You do not have to choose a machine by yourself. Talk to suppliers and experts before you buy. They can answer your questions and give advice for your needs. Experts can help you match the machine to your product and packaging process. They might also show you how to fix common problems or suggest upgrades for better results.

Ask for a demo or case study. These can show you how the machine works in real life. You can also ask for references from other customers. This step helps you feel sure about your choice.

자주하는 질문

What products can you package with a vertical form fill seal machine?

You can use the machine for powders, 액체, 간식, 작살, and small hardware. It works in many industries like food, 약, and pet supplies. Always test your product first to make sure the machine works for you.

How do you maintain a vertical form fill seal machine?

Clean the machine every day and look for parts that are worn out. Follow the care steps from your supplier’s guide. Taking care of your machine helps it last longer and keeps your packaging safe.

Can you connect a VFFS machine to other equipment?

예, you can link your VFFS machine to weighing, 라벨링, or printing systems. This setup helps you automate your packaging and work faster. Always check if the machines work together before you buy new ones.

How do you choose the right bag size for your product?

Measure your product’s weight and how much space it takes up. Pick a bag size that fits your product and keeps it safe when shipping. Many machines let you change bag sizes for different products.

What safety features should you look for?

Look for emergency stop buttons, safety guards, and sensors on the machine. These features help keep workers safe and stop accidents. Machines with clear safety labels are easier and safer to use.