完璧な状態で店の棚に到達するすべての製品は、そのパッケージについての物語を語っています. 食べ物で, 医学, および産業部門, 熱成形包装機はその物語の中心に座っています. 彼らは形をします, シール, 高速で商品を保護します, 一貫した品質とスケーラブルな出力を必要とするあなたのような企業にとってそれらを不可欠にする.

この記事で, 熱成形包装機とは何かを学びます, 8つの大手グローバルメーカーを発見してください, 適切なパートナーを選択するための実用的なヒントをご覧ください パッケージラインを強化します.

上 8 世界の熱成形包装機械メーカー

クイック比較テーブル

メーカー | 国 | 設立 | 主な製品 | 製造の利点 |

|---|---|---|---|---|

Illig Maschinenbau gmbh & co. KG | ドイツ | 1946 | 熱成形機, カビ, パッケージライン | 高精度, エネルギー効率, 高度な金型技術, グローバルサービスサポート |

Kiefel Gmbh | ドイツ | 1955 | 熱成形機, 押出ライン, 自動化ソリューション | 高自動化, 柔軟性, 重要なr&D投資, 広範なグローバルサービスネットワーク |

マルチバックグループ | ドイツ | 1961 | 熱成形包装機, 真空包装システム, マップユニット | ハイパフォーマンス, 信頼性, 使いやすいインターフェイス, さまざまなアプリケーションに適しています |

ブラウンマシングループ (BMG) | アメリカ合衆国 | 1985 | 硬質熱成形機, 産業用パッケージソリューション | 厚い材料に適しています, 堅牢なデザイン, 柔軟性が高い, 強力なエンジニアリングサポート |

Gabler Thermoform Gmbh & co. KG | ドイツ | 1974 | フードパッケージング熱成形機, 自動化システム | 高精度形成, クイックカビの変更, エネルギー効率の高い設計, 強力な技術サポート |

ガイスAG | ドイツ | 1948 | 熱成形機, CNC処理システム | 高い信頼性, さまざまな材料に適応できます, 効率とコストのバランス, 簡単なメンテナンス |

セルフグループCOMI S.R.L | イタリア | 1973 | 熱成形機, マップパッケージングシステム | モジュラー設計, 柔軟性が高い, ヨーロッパの基準へのコンプライアンス, 強力な技術サポート |

ウルマパッケージ | スペイン | 1957 | 熱成形機, パッケージングシステム | 使いやすいインターフェイス, エネルギー効率の高い設計, 高自動化, さまざまなアプリケーションに適しています |

Illig Maschinenbau gmbh & co. KG (ドイツ)

会社の概要: に設立されました 1946, ヘルブロンに本社を置いています, ドイツ. Illigは熱成形技術のグローバルリーダーに成長しました, 機械を供給します 100 国. 同社はイノベーションを強調しています, 信頼性, 長期的な顧客パートナーシップ.

主な製品: 食品用の高速熱成形機, 医学, 消費財パッケージ.

製造の利点: 例外的な精度と再現性, 耐久性のあるフレームとコンポーネント, 複雑な形状の高度な金型テクノロジー, エネルギー効率の高いシステム, そして、世界中の強力なアフターセールスサポート.

Kiefel Gmbh (ドイツ)

会社の概要: に設立されました 1948, フリラスに本社を置いています, ドイツ. Kiefelは、自動化と柔軟なパッケージングソリューションの専門知識で認められています, 食品から医療および自動車までの産業にサービスを提供しています. 会社は多額の投資をしています r&D パッケージングテクノロジーの最前線にとどまること.

主な製品: 熱成形機, 押出ライン, 完全に自動化されたパッケージングソリューション.

製造の利点: 正確なサイクル規制を備えた高性能制御システム, 堅牢な自動化, さまざまな製品の柔軟な形成機能, 包括的なグローバルサービスサポートが最小限のダウンタイムを確保します.

マルチバックグループ (ドイツ)

会社の概要: に設立されました 1961, Wolfersschwendenに本社を置いています, ドイツ. Multivacは、統合されたパッケージングソリューションのグローバルリーダーです, イノベーションと高品質のエンジニアリングで知られています. 世界中の食品や医療包装に強い存在感を持っています.

主な製品: Thermoform-Fill-Sealマシン, 真空包装システム, 地図 (修正された雰囲気のパッケージ) 機械.

製造の利点: 信頼性の高い大量のパフォーマンス, 使いやすいインターフェイス, 敏感な製品の衛生的な設計, 一貫した品質の汎用性の高いアプリケーション.

ブラウンマシングループ (BMG) (アメリカ合衆国)

会社の概要: に設立されました 1985, カンザスシティに本社を置いています, アメリカ合衆国. BMGは、産業用および消費者パッケージ用のヘビーゲージの熱成形機を専門としています. 同社は、厳しい生産要件を処理できるエンジニアリング耐久性のある機械に焦点を当てています.

主な製品: トレイ用の剛性熱成形機, コンテナ, その他の産業用パッケージ.

製造の利点: 厚くて硬い素材にカスタマイズ可能, 長い生産のための堅牢な構造, さまざまな製品形状の柔軟性, 複雑なアプリケーションに対する強力なエンジニアリングサポート.

Gabler Thermoform Gmbh & co. KG (ドイツ)

会社の概要: に設立されました 1959, Laufに本社を置いています, ドイツ. Gablerは、高精度の形成マシンとエネルギー効率の高い設計で知られています. 会社は食べ物を提供しています, 医学, 世界中の消費財セクター.

主な製品: フードトレイ用の熱成形機, 医療包装, そして消費財.

製造の利点: 正確な形成による最小限の材料廃棄物, より速い生産シフトのためのクイックダイチェンジシステム, エネルギー効率の高いデザイン, 高い形成精度, 強力な技術サポート.

ガイスAG (ドイツ)

会社の概要: に設立されました 1980, Pforzheimに本社を置いています, ドイツ. GEISSは、中〜大量の熱成形ソリューションを専門としています, 幅広い材料や製品に適した柔軟な機械を提供する.

主な製品: 柔軟な材料処理を備えた熱成形機, 封印, および切断機能.

製造の利点: 信頼できる形成とシーリングパフォーマンス, さまざまなフィルムの厚さに適応できます, バランスの取れた効率とコスト, 継続的な操作のための簡単なメンテナンス.

セルフグループCOMI S.R.L (イタリア)

会社の概要: に設立されました 1964, イタリアに本社を置いています. Amut-Comiは、柔軟で硬い包装機械を専門としています. 同社は、さまざまな生産要件とカスタマイズへの簡単な適応を可能にするために、モジュラー設計を強調しています.

主な製品: 真空用の熱成形機, 地図, および標準のパッケージングアプリケーション.

製造の利点: 簡単なアップグレードとカスタマイズのためのモジュラー構造, さまざまな製品タイプの汎用性の高いソリューション, ヨーロッパの設計と衛生基準のコンプライアンス, グローバルクライアント向けの強力な技術サポート.

ウルマパッケージ (スペイン)

会社の概要: に設立されました 1957, オニャーティに本社を置いています, スペイン. Ulmaは、食品および非食品包装ソリューションの重要なプレーヤーです, 完全に自動化された熱成形ラインとパッケージングテクノロジーの革新で知られる.

主な製品: フォーミングを統合する完全に自動化された熱成形機, 充填, とシーリング.

製造の利点: ユーザーフレンドリーなインターフェイスと操作, 衛生中心の設計, エネルギー効率の高い生産, 大量の出力用の信頼できる自動化, 一貫した製品品質.

熱成形包装機とそのタイプ

あ 熱成形包装機 プラスチックシートを正確なパッケージング形状に変えるために使用するツールです. プラスチックフィルムが柔らかく柔軟になるまで、プラスチックフィルムを加熱することから始めます. 次に、機械を使用して加熱シートをキャビティに形成します, プレッシャー, または真空. 形状の準備ができたら, キャビティを製品で満たすことができます, ふたやフィルムで密封します, 余分な素材をトリミングします. このプロセスは、出荷または表示の準備ができている完成したパッケージを提供します.

熱成形包装機の種類

熱成形パッケージマシンを見ると, 形成後のパッケージの処理方法に基づいてグループ化できることを理解することが重要です. この分類は、マシンがパッケージ内の製品を保存および保護する方法に焦点を当てています. これを知ることはあなたに役立ちます マシンを選択します それはあなたの特定のニーズに合っています, 新鮮な食べ物をパッケージ化しているかどうか, 冷えた製品, またはドライアイテム.

熱成形真空パッケージングマシン

形成後, 機械は空気を除去します (真空を作成します) または、シールする前にパッケージをガスで埋めます

一般的に新鮮または 腐りやすい食品 肉など, チーズ, とシーフード

パッケージ内の酸素を減らすことにより、保存期間を延長し、製品の品質を維持するのに役立ちます

地図 (修正された雰囲気のパッケージ) 熱成形機

形成後, 機械は窒素などの保護ガスでパッケージを埋めます (n₂) または二酸化炭素 (co₂)

調理済みの食品の保存期間を延長します, セミフィニッシュ製品, そして冷やした生鮮食品

風味を維持するために制御された雰囲気のパッケージが必要なときに理想, 色, と新鮮さ

標準 / 非視力式熱成形マシン

トレイまたはキャビティの形成とシーリングのみを実行します, 真空またはガス注入なし

よく使用されます 医療消耗品, エレクトロニクストレイ, キャンディー, その他の乾燥製品

真空やガス包装が必要ない場合に、よりシンプルで費用対効果の高いソリューションを提供します

熱成形パッケージマシンメーカーの選択方法

業界の経験と評判を評価します

堅実な実績を持つメーカーを選択することは、信頼できる生産に不可欠です. あなたはあなたの特定のセクターのための熱成形機の専門知識を証明したパートナーが必要です, 食べ物かどうか, 医学, または産業用パッケージ. 経験豊富な企業には、エンジニアリングの慣行が洗練されています, テストされたワークフロー, そして 信頼できるアフターセールスサポート. 品質で知られているメーカーを選択することにより, 運用上のリスクを減らし、パッケージングプロセスがスムーズに実行されるようにします.

技術的な能力と機械の柔軟性を評価します

マシンのパフォーマンスと適応性が重要な要素です. 調整可能な形成オプションなどの機能を探してください, クイック金型変更システム, エネルギー効率の高いデザイン. これらを使用すると、効率を失うことなく、製品やパッケージング形式を迅速に切り替えることができます. 最新の自動化と直感的な制御システムもオペレーターのエラーを最小限に抑えます, 時間を節約して保証します 一貫した製品品質. ここの柔軟性は、進化する市場の需要を満たす能力に直接影響します.

サポートネットワークとカスタマイズオプションを検討してください

信頼できるグローバルサポートとカスタマイズは大きな違いを生むことができます. 強力なサービスチームを持つメーカーは、問題を迅速にトラブルシューティングするのに役立ちます, ダウンタイムを最小化します. モジュラーまたは構成可能なマシンでは、システムをパッケージングのニーズに合わせて調整できます, 真空かどうか, 地図, または標準形成. あなたの生産目標を理解しているパートナーと協力すると、より高い効率が保証されます, 一貫した品質, 長期的な競争力.

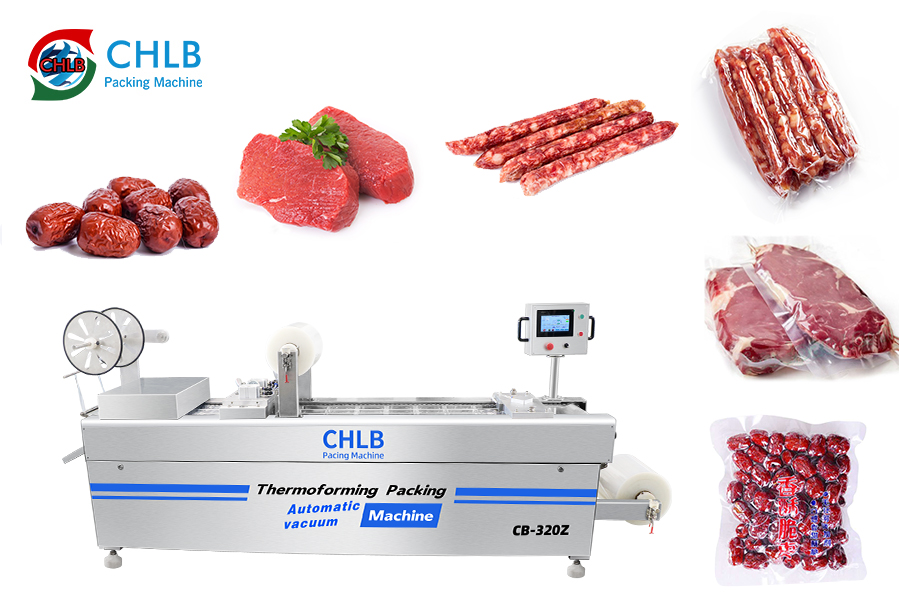

CHLBとのパートナー

一緒に働く CHLB あなたの本当の生産圧力を理解しているパートナーを獲得することを意味します. 当社の熱成形パッケージマシン 柔軟性のために構築されています, クイックチェンジオーバー, そして正確な形成, したがって、時間を失うことなく多様な製品を処理できます. また、透明な技術データも提供しています, だからあなたは常に各モデルに何を期待するかを知っています.

機械自体を超えて, ダウンタイムを最小限に抑えるために、レスポンシブサービスと高速の予備パーツ配達に焦点を当てています. トレーニングサポートの恩恵を受けることができます, クリアなパフォーマンス保証, フォーミングの深さをカスタマイズするオプション, フィルム幅, または、正確なニーズに合わせてシーリング方法. 生産を合理化し、パッケージングの品質を上げる準備ができている場合, に手を差し伸べます CHLB 今日はあなたのビジネスに最適なソリューションについて話し合うために.