Ogni minuto la tua linea di produzione si adatta al minimo costa denaro. Ogni sigillo imperfetto rischia la tua reputazione. Nella produzione, Scegliere il sigillo di riempimento verticale sbagliato (VFFS) La macchina non è solo una supervisione: è un errore critico aziendale.

Immagina una macchina VFFS ad alte prestazioni. 300 sacchetti al minuto, confezionando perfettamente i tuoi liquidi, polveri, o cereali con perfetta coerenza. La macchina giusta diventa il battito cardiaco della tua linea di produzione, Costruito per crescere con la tua attività.

Non tutte le macchine VFFS sono create uguali. La differenza tra risultati affidabili e incubi di manutenzione si riduce alla qualità della costruzione, materiali, e compatibilità con le tue esigenze. Questa guida rivela ciò che separa i leader del settore da costosi errori.

Cos'è una macchina per guarnizione di riempimento in forma verticale?

Panoramica VFFS

UN macchina verticale di riempimento e sigillatura del modulo, o macchina VFFS, è un tipo di attrezzatura da imballaggio. Aiuta a fare, riempire, e sigillare i sacchetti automaticamente. Inizi mettendo un tiro di film nella macchina. La macchina modella il film in un tubo. Quindi riempie il tubo con il tuo prodotto. Dopo di che, sigilla il tubo per creare una borsa finita. Questo è chiamato il principio di funzionamento della macchina per guarnizioni di riempimento verticale. Puoi usare una macchina VFFS per molte cose. Funziona per le polveri, liquidi, spuntini, e cibi congelati.

Macchine VFFS vieni in molti modelli e dimensioni. Ogni modello ha caratteristiche speciali per diversi settori. La tabella seguente elenca alcuni modelli di macchina VFFS comuni. Mostra i loro dettagli tecnici e dove potresti usarli:

Confronto delle serie di prodotti

Parametro | Serie PA (Polvere) | Serie PM (Granello) | Serie PP (Liquido) | Serie PV (Volumetrico) |

|---|---|---|---|---|

Modelli | ||||

Applicazione | Prodotti in polvere | Prodotti granulari | Prodotti liquidi | Vari prodotti sfusi |

Dispositivo di misurazione | Dosi Augs | Pesatore multihead | Pompa liquida | Riempitivo a coppa volumetrica |

Specifiche tecniche (Lo stesso per tutte le serie)

Specifica | 420 Modello | 520 Modello | 680 Modello |

|---|---|---|---|

Larghezza massima di film di rollio | 420mm | 520mm | 720mm |

Larghezza della borsa massima | 200mm | 250mm | 350mm |

Lunghezza della borsa massima | 300mm | 400mm | 480mm |

Velocità di imballaggio | 5-60 sacchetti/min (Secondo il peso della borsa singola) | 5-60 sacchetti/min (Secondo il peso della borsa singola) | 5-60 sacchetti/min (Secondo il peso della borsa singola) |

Campo di misura | 150-1200ml | 3000ml | 6000ml |

Materiale da imballaggio | Film composito (UP/CPP, UP/PE, PET/PE, NY/PE ecc.) o film PE puro | Film composito (UP/CPP, UP/PE, PET/PE, NY/PE ecc.) o film PE puro | Film composito (UP/CPP, UP/PE, PET/PE, NY/PE ecc.) o film PE puro |

Consumo d'aria | ≥0.65MPA | ≥0.65MPA | ≥0.65MPA |

Tensione di potenza | 220V/380V, 50Hz/60Hz, 1 fase/3 fase | 220V/380V, 50Hz/60Hz, 1 fase/3 fase | 220V/380V, 50Hz/60Hz, 1 fase/3 fase |

Energia | 2chilowatt | 2.5chilowatt | 3.5chilowatt |

Peso netto | 550Kg | 650Kg | 720Kg |

Perché la durata è importante

Una forte macchina per guarnizioni di riempimento verticale continua a lavorare. Vuoi una macchina che possa riempire e sigillare tutto il giorno senza rompersi. Le nuove macchine VFFS usano materiali resistenti come l'acciaio inossidabile. Hanno anche facili controlli di pulizia. Queste cose ti aiutano a pulire rapidamente e fermare di meno per le riparazioni.

Mancia: Le macchine con tenuta ad ultrasuoni rendono forte, guarnizioni a prova di perdite. Questo mantiene il tuo prodotto sicuro e la tua confezione sta bene.

Le macchine VFFS di oggi utilizzano la tecnologia intelligente. Molti hanno AI, IoT, e sensori per guardare come funzionano. Queste funzionalità ti aiutano a trovare problemi in anticipo. Questo significa che la tua macchina dura più a lungo. Le macchine VFFS veloci possono riempire e sigillare fino a 40,000 unità ogni ora. Questo aiuta le grandi fabbriche a fare molti prodotti.

Cosa cercare in una macchina per guarnizione di riempimento verticale durevole

Vuoi un VFFS che possa funzionare tutto il giorno e tenere il passo con le tue esigenze. Dovrebbe dare risultati forti ogni anno. Il diritto Macchina di imballaggio VFFS ti aiuta a evitare problemi e mantiene il tuo processo di riempimento facile.

Qualità costruttiva

La qualità costruttiva è molto importante quando controlli le macchine VFFS. Una cornice forte e una buona build aiutano la macchina a lavorare per molte ore. Dovresti cercare queste cose:

Frame robusto: Un telaio pesante mantiene stabile la macchina per l'imballaggio VFFS quando si riempie e sigilla. Questo smette di tremare e aiuta a rendere ogni borsa lo stesso.

Ingegneria di precisione: Le macchine con parti strette e buoni adattamenti funzionano meglio. Riempi e sigillano borse con meno rifiuti e meno marmellate.

Tecnologia di sigillatura brevettata: Alcuni macchinari di imballaggio VFFS utilizzano due passaggi per sigillare i sacchetti. Questo rende i sigilli più forti e più sicuri, Quindi la macchina funziona meglio.

Set di formazione specializzati: Se si utilizzano film basati su carta, set di formazione speciali aiutano questi film a muoversi senza intoppi. Questo smette di strappare e mantiene stabile il tuo processo di riempimento.

Meccanismi di distorsione del potere: Questi sistemi spingono il film da dietro. Questo riduce la possibilità di strappare il film quando la macchina si riempie e sigilla.

Nota: Il modo in cui il film scorre sulle parti della macchina può cambiare quanto funziona la macchina per l'imballaggio VFFS. Se non lo controlli, La tua macchina può logorarsi o rompersi. Una buona ingegneria aiuta la tua macchina a funzionare bene.

Dovresti anche pensare a quanto durerà il tuo imballaggio VFFS. A volte, Puoi aggiungere nuove parti o “Aggiornamenti verdi” Alla tua vecchia macchina. Questo ti aiuta a utilizzare nuovi film di imballaggio e fa funzionare bene la macchina senza acquistarne una nuova.

Scelte materiali

Le scelte materiali sono una parte importante di cosa cercare in una macchina per guarnizione di riempimento verticale durevole. I materiali giusti aiutano i VFS a durare attraverso l'uso e la pulizia quotidiani. Ecco alcuni materiali comuni che vedrai in buone macchine VFFS:

Materiale | Benefici | Usi comuni nelle macchine VFFS |

|---|---|---|

Acciaio inossidabile | Non arrugginito o corrode. Facile da pulire. Gestisce sostanze chimiche forti. | Cornici, parti di contatto, tubi di riempimento, sigillando le mascelle |

CHLB (Bainite a basso contenuto di cromo) | Molto difficile e non si consuma velocemente. Gestisce molto stress. | Sigillando le mascelle, Tagliare le lame |

Alluminio anodizzato | Leggero ma forte. Non arrugginito. | Parti della macchina senza contatto |

L'acciaio inossidabile è la scelta migliore per la maggior parte delle macchine per l'imballaggio VFFS, Soprattutto nelle fabbriche di cibo e chimico. Mantiene il tuo processo di riempimento sicuro e pulito. Le parti CHLB durano più a lungo e aiutano la macchina a funzionare bene anche con un uso pesante. L'alluminio anodizzato rende la macchina più leggera ma ancora forte.

Mancia: Chiedi al tuo fornitore i materiali nei punti di riempimento e sigillatura. Queste parti vengono utilizzate di più e hanno bisogno della migliore protezione.

Compatibilità del prodotto e dell'imballaggio

Tipi di prodotto

Ogni tipo di prodotto ha bisogno di qualcosa di diverso. Polveri, granuli, liquidi, e i solidi agiscono tutti a modo loro. La gravità aiuta le polveri e i liquidi a muoversi facilmente in borse. Questo rende il ripieno liscio per questi prodotti. Ma cibi morbidi come patatine o caramelle possono rompersi se cadono troppo velocemente. È necessario utilizzare il giusto sistema di riempimento per ogni prodotto. Questo mantiene bene il processo di imballaggio.

Alcune macchine hanno alimentatori speciali per oggetti appiccicosi o fragili. Altri usano coclers o pompe per liquidi e paste spesse. Le aziende di cibo e medicina devono seguire rigide regole di igiene. Le macchine per l'imballaggio VFFS con parti facili da pulire aiutano a soddisfare queste regole. Una buona sigillatura aiuta anche a mantenere le cose al sicuro.

Mancia: Testa il tuo prodotto con la macchina VFFS prima di acquistare. Questo mostra se la macchina può imballare il tuo prodotto senza danni.

Materiali di imballaggio

Il materiale di imballaggio che scegli cambia come funziona la macchina VFFS. Puoi usare la plastica, lamina metallizzata, carta, o tessuto. Ognuno ha i suoi buoni punti e problemi. I film in plastica sigillano velocemente e mantengono l'aria e l'acqua. Il foglio metallizzato dà ulteriore protezione per le cose che devono rimanere fresche. Carta e tessuto sono migliori per l'ambiente, ma potrebbe aver bisogno di una sigillatura speciale.

Tipo di materiale | Benefici | Usi comuni |

|---|---|---|

Plastica | Sigillatura rapida, barriera di umidità | Spuntini, polveri, liquidi |

Lamina metallizzata | Alta barriera, durata lunga | Caffè, spezie, cibo |

Carta | Eco-friendly, stampabile | Cibi secchi, tè, cereali |

Tessuto | Traspirante, Aspetto unico | Articoli speciali, produrre |

Più aziende vogliono utilizzare un packaging migliore per il pianeta. I film riciclabili o compostabili stanno diventando popolari. Questi nuovi materiali possono cambiare il modo in cui la macchina VFFS sigilla i sacchetti. Potrebbe essere necessario cambiare calore o pressione per ottenere un buon sigillo. Alcune macchine hanno controlli che aiutano con questi materiali.

Nota: È importante essere flessibili con l'imballaggio. Le migliori macchine VFFS ti consentono di cambiare facilmente materiali e dimensioni delle sacchetti. Questo ti aiuta a tenere il passo con ciò che i clienti desiderano.

Velocità ed efficienza

Tassi di output

Quando scegli una macchina VFFS, Vuoi sapere quanto velocemente può funzionare. La velocità conta in ogni linea di imballaggio. Alto Tassi di output aiutarti a incontrare grandi ordini e mantenere felici i tuoi clienti. Molte macchine per l'imballaggio VFF possono riempire e sigillare centinaia di sacchetti ogni minuto. Alcuni modelli avanzati raggiungono 300 sacchetti al minuto. Questo livello di velocità può cambiare il modo in cui gestisci la tua attività.

Dovresti guardare il tipo di prodotto che desideri confezionare. Polveri, liquidi, e gli snack si muovono tutti a velocità diverse attraverso la macchina. I prodotti più leggeri spesso consentono un imballaggio più veloce. I prodotti pesanti o appiccicosi possono rallentare il processo. Puoi controllare il foglio tecnico della macchina per la sua velocità massima. Testa sempre il tuo prodotto per vedere la velocità di output reale.

Cambiamento senza strumenti

Il cambio senza strumenti è una caratteristica chiave nelle moderne macchine per l'imballaggio. È possibile passare da diverse dimensioni di sacchetti o materiali di imballaggio senza utilizzare strumenti speciali. Questo ti fa risparmiare tempo e mantiene la tua linea in esecuzione. I cambi rapidi ti aiutano a rimanere flessibile. Puoi rispondere rapidamente a nuovi ordini o tendenze di imballaggio.

Molte macchine VFFS ora hanno parti facili da regolarsi. Puoi spostare le guide, Cambia i tubi di formazione, o scambia le mascelle sigillate a mano. Ciò significa meno tempi di inattività e maggiore efficienza nel tuo lavoro quotidiano.

Passi meno tempo a fermare la macchina.

Riduci il rischio di errori durante la configurazione.

Mantieni alta la qualità dell'imballaggio.

Manutenzione e pezzi di ricambio

Facilità di manutenzione

Vuoi che la tua macchina per guarnizione di riempimento verticale funzioni senza intoppi ogni giorno. Una facile manutenzione ti aiuta a mantenere la macchina in ottima forma.

Molte macchine moderne hanno etichette chiare e parti codificate. Queste funzionalità ti aiutano a trovare ciò di cui hai bisogno velocemente. Alcune macchine hanno persino programmi di pulizia integrati. Premi un pulsante, E la macchina si pulisce. Questo mantiene la tua area di imballaggio sicura e pulita.

Mancia: Controlla se la macchina viene fornita con un file Manuale di manutenzione. Un buon manuale ti dà guide e immagini passo-passo. Questo ti aiuta a risolvere piccoli problemi da solo.

Disponibilità dei pezzi di ricambio

I pezzi di ricambio svolgono un ruolo importante nel far funzionare la macchina VFFS. Devi sapere che puoi ottenere parti rapidamente quando qualcosa si esaurisce. Chiedi al tuo fornitore la loro politica dei pezzi di ricambio prima di acquistare. Alcune aziende mantengono parti comuni in stock e le spediscono velocemente.

Nota: Chiedi sempre un elenco di pezzi di ricambio consigliati quando acquisti la macchina. Questo elenco ti aiuta a pianificare in anticipo ed evitare lunghi tempi di inattività.

Supporto fornitore e post-vendita

Reputazione

Scegliere una macchina per guarnizione di riempimento in forma verticale significa controllare la reputazione del fornitore. Un buon fornitore ti fa sentire al sicuro per la tua scelta. Vuoi un'azienda che ti aiuti se qualcosa va storto. I fornitori di fiducia hanno clienti felici e buone recensioni. Rispondono rapidamente alle tue domande e risolvono rapidamente problemi.

I fornitori con una forte reputazione ti aiutano a evitare problemi. Danno un supporto migliore e inviano pezzi di ricambio più velocemente.

È più facile utilizzare la garanzia con un fornitore di fiducia.

I buoni fornitori possono avere uffici o partner vicino a te. Questo significa che ottieni aiuto senza aspettare troppo a lungo.

Le aziende con grande reputazione vendono macchine che durano più a lungo e si rompono meno spesso.

Nota: Vedi sempre se il fornitore ha un supporto post-vendita vicino a te. Questo può farti risparmiare tempo e denaro se hai bisogno di aiuto.

Formazione e servizio

Il supporto post-vendita non riguarda solo il fissaggio di macchine. Hai anche bisogno di formazione e servizio per far funzionare bene la macchina VFFS. I buoni fornitori insegnano al tuo team come usare e prendersi cura della macchina. Potrebbero dare lezioni di persona, Video online, o manuali facili. La formazione aiuta i tuoi lavoratori a evitare errori e mantengono tutti al sicuro.

Trova fornitori che offrono formazione per operatori e guide semplici.

Alcune aziende possono controllare la macchina da lontano utilizzando strumenti remoti. Questo aiuta a risolvere i problemi velocemente.

Ottenere i pezzi di ricambio rapidamente è importante. Non vuoi che la tua macchina si fermi per molto tempo.

Supporto locale significa che puoi risolvere immediatamente i problemi.

Mancia: Chiedi informazioni sulla garanzia e sui piani di servizio prima di acquistare. Un buon piano di servizio protegge i tuoi soldi e mantiene la macchina in funzione per anni.

Integrazione e impronta

Compatibilità del sistema

Vuoi che la tua macchina per guarnizioni di riempimento verticale funzioni con le altre macchine. Compatibilità del sistema significa che la nuova macchina può unirsi alla linea di produzione attuale. Controlla se la macchina VFFS può connettersi alla pesatura, Riempimento, o macchine per l'etichettatura. Alcune macchine utilizzano protocolli di comunicazione comuni come Ethernet/IP o Modbus. Questi protocolli aiutano le tue macchine a condividere informazioni.

Se vuoi più automazione, Scegli una macchina VFFS che funzioni con armi robotici o trasportatori. Questo rende il tuo processo di imballaggio più veloce e più facile. Puoi anche collegare la macchina VFFS ai sistemi di dati. Questo ti consente di guardare i numeri di produzione e trovare problemi in anticipo.

Mancia: Chiedi al tuo fornitore un elenco di apparecchiature e software che funziona con la macchina. Questo ti aiuta a evitare di spendere soldi extra più tardi.

Ecco una semplice lista di controllo per la compatibilità del sistema:

La macchina può connettersi ai trasportatori o alle alimentatori?

Funziona con le tue macchine per l'etichettatura o?

Puoi collegarlo ai tuoi sistemi di controllo di qualità?

Usa protocolli di comunicazione comuni?

Spazio per pavimenti

Devi sapere quanto spazio utilizzerà la tua macchina VFFS. Lo spazio del pavimento è importante in ogni fabbrica. Alcune macchine sono piccole e si adattano a punti stretti. Altri hanno bisogno di più spazio per i rotoli di film, alimentatori, o per la pulizia.

Misura il tuo spazio prima di acquistare una macchina. Controlla le dimensioni della macchina nel foglio tecnico. Lasciare spazio extra per i lavoratori da muoversi e pulire. Se vuoi crescere, Pensa a quanto spazio avrai bisogno in seguito.

Costo e ROI

In anticipo vs. Costi a lungo termine

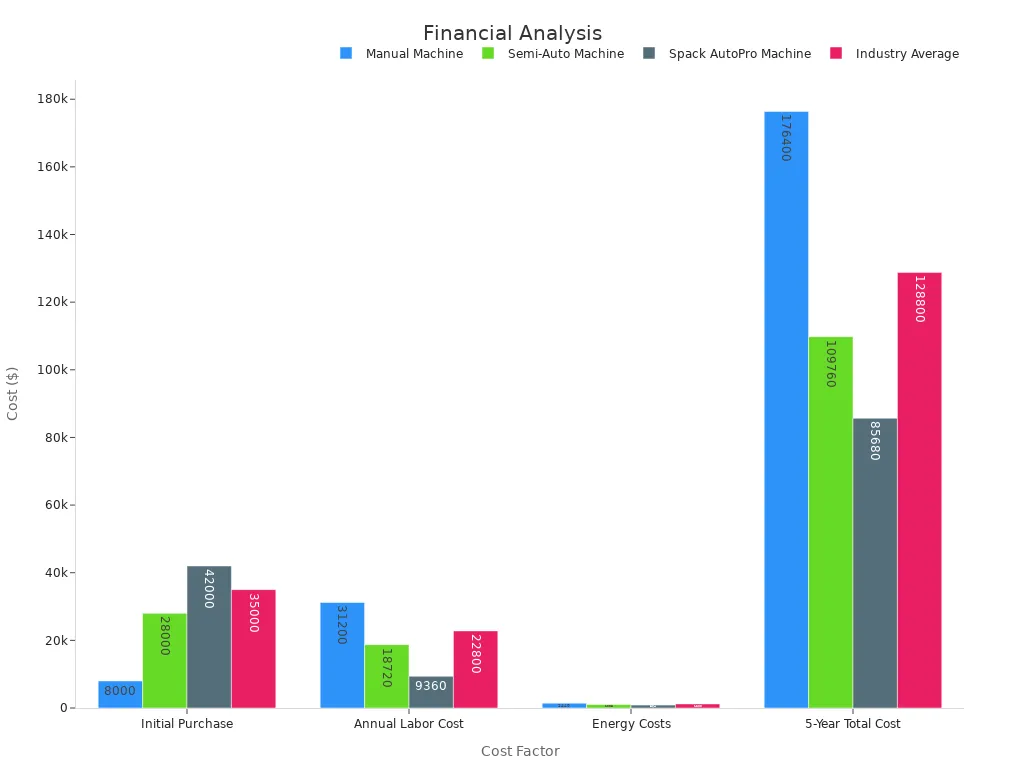

Quando si acquista una macchina per guarnizioni di riempimento verticale, Devi guardare oltre il prezzo adesivo. Il costo iniziale è solo una parte dell'investimento totale. Paghi anche per il lavoro, energia, e rifiuti materiali nel tempo. Questi costi in corso possono sommarsi rapidamente.

Puoi vedere che le macchine automatiche costano all'inizio. Tuttavia, Ti fanno risparmiare denaro sul lavoro e sui rifiuti. In cinque anni, Il costo totale della proprietà diminuisce. Ottieni più valore da il tuo investimento.

Mancia: Controlla sempre i costi a lungo termine prima di decidere. Un prezzo iniziale più elevato può significare risparmi più grandi in seguito.

Valutazione del ROI

Vuoi sapere quanto velocemente il tuo investimento paga. Ritorno sugli investimenti (ROI) mostra quanto velocemente recuperi i tuoi soldi. Le macchine VFFS automatiche spesso ti danno un ROI più veloce perché funzionano più velocemente e sprecano meno materiale.

Un esempio del mondo reale mostra questo in azione. Una società di spezie in Texas ha acquistato una macchina VFFS per $34,000. Hanno restituito i loro soldi in soli otto mesi. Ciò è accaduto perché la macchina ha abbreviato più borse all'ora e ha usato meno lavoro.

Puoi usare il ROI per confrontare le macchine. Guarda quanto risparmia sul lavoro, energia, e rifiuti. Più velocemente raggiungi il rimborso, Migliore il tuo investimento. Chiedi sempre ai fornitori numeri reali e casi studio. Questo ti aiuta a fare una scelta intelligente per la tua attività.

Sicurezza e conformità

Caratteristiche di sicurezza

È importante proteggere i lavoratori e i prodotti quando si utilizzano una macchina per guarnizioni di riempimento verticale. Le nuove macchine VFFS hanno molte caratteristiche di sicurezza per proteggere le persone e le merci. Queste funzionalità aiutano a fermare gli incidenti e continuano a funzionare bene gli imballaggi.

Imballaggio evidente mostra se una borsa è stata aperta prima che il cliente la ottenga. Questo è molto importante per cibo, medicinale, e altri prodotti le persone usano.

La tenuta automatizzata chiude ogni pacchetto saldamente. Questo aiuta a fermare le perdite e le fuoriuscite.

I film di barriera tengono fuori l'acqua, aria, e sporcizia. I tuoi prodotti rimangono freschi e sicuri più a lungo.

Alcune macchine usano la pressione dell'aria o gli spazi chiusi per tenere fuori germi e polvere.

Parti a rilascio rapido e angoli lisce rendono la pulizia semplice. Puoi toglierti le parti velocemente e lavarle bene. Questo aiuta a impedire ai batteri di crescere.

Mancia: Vedi sempre se la tua macchina ha caratteristiche di tracciabilità. Questi ti consentono di tenere traccia di ogni pacchetto dall'inizio alla fine. Questo semplifica i richiami e gli audit.

Standard normativi

Devi seguire Regole rigorose Quando si imballi, medicinale, o altri elementi sensibili. Le macchine VFFS soddisfano molti standard importanti per aiutarti a seguire le regole.

Standard o funzionalità | Cosa significa per te |

|---|---|

La tua macchina è sicura per il cibo e soddisfa le leggi sulla sicurezza. | |

Acciaio inossidabile per alimenti | Tutte le parti che toccano il prodotto non arrugginano e sono facili da pulire. |

Design igienico | Bordi lisci e sistemi puliti in sede abbassano il rischio di germi. |

Filtrazione Hepa | L'aria all'interno della macchina rimane pulita e mantiene i prodotti al sicuro. |

Protocolli di convalida | Puoi mostrare le tue fasi di pulizia e sicurezza. Questo aiuta con gli audit. |

Molte macchine seguono anche le regole della sicurezza alimentare del mondo e possono avere certificazioni extra come EHEDG. Questi passaggi ti aiutano a evitare problemi legali e proteggere il tuo marchio. Caratteristiche cinematografiche speciali, Come la protezione UV o gli strati antistatici, Può aiutarti a soddisfare le regole speciali per la tua attività.

Nota: Seguire questi standard può ridurre i rischi di contaminazione fino a 90%. Chiedi sempre al tuo fornitore la prova di conformità prima di acquistare.

Opzioni automatiche di riempimento del formato verticale

Vantaggi di automazione

Ci sono molti tipi di macchine per guarnizioni di riempimento in forma verticale. I tipi principali sono automatici e semiautomatici. Una macchina automatica di riempimento di forma verticale fa quasi tutto da solo. Fa, si riempie, e sigillano borse con scarso aiuto da parte delle persone. Le macchine semi-automatiche hanno bisogno di più aiuto da parte dei lavoratori. Potrebbe essere necessario inserire materiali o iniziare ogni passaggio.

Le macchine automatiche funzionano molto velocemente. Possono mettere in valigia centinaia di borse ogni minuto. Questa velocità ti aiuta a finire grandi ordini e tenere il passo con ciò che la gente vuole. Queste macchine sono anche più accurate. Misurano ogni prodotto e sigillano ogni borsa allo stesso modo. Ciò significa che sprechi di meno e commetti meno errori.

Ecco un semplice confronto:

Caratteristica | VFF automatici | VFF semi-automatici |

|---|---|---|

Velocità | Molto alto | Medio |

Lavoro necessario | Basso | Medio-alto |

Precisione | Alto | Medio |

Meglio per | Grandi lotti | Piccoli lotti |

Mancia: Se vuoi usare meno manodopera e preparare più borse, Scegli una macchina automatica di riempimento in forma verticale.

Imballaggio flessibile

Hai bisogno che la tua linea di imballaggio sia flessibile. Prodotti e clienti diversi vogliono forme e dimensioni di sacchetti diversi. Macchine per guarnizioni di riempimento verticale automatico consentono di cambiare rapidamente gli stili di imballaggio. Puoi fare le valigie, polveri, o liquidi con la stessa macchina. Si modificano solo alcune impostazioni o parti.

Alcune macchine possono utilizzare molti materiali di imballaggio. Puoi usare la plastica, sventare, o film di carta. Questo ti aiuta a dare ai clienti ciò che vogliono e provare nuove idee. Puoi fare cuscini, Borse a gesso, o buste stand-up.

Puoi imballare piccoli o grandi lotti.

Puoi provare nuove idee per l'imballaggio senza acquistare un'altra macchina.

Puoi far funzionare la tua linea con meno fermi.

Nota: Le scelte di imballaggio flessibili aiutano la tua azienda a crescere e stare al passo con gli altri.

Guida dell'acquirente alle macchine VFFS

Elenco di controllo della valutazione

Vuoi scegliere il meglio macchina verticale di riempimento e sigillatura del modulo. Usa questo Elenco di controllo Per aiutarti a confrontare le macchine:

Controlla quanto devi fare le valigie ogni giorno. Assicurati che la macchina possa tenere il passo con il tuo lavoro.

Pensa a cosa farai le valigie. Solidi, polveri, e i liquidi potrebbero aver bisogno di diverse funzionalità della macchina.

Misura il tuo spazio. La macchina deve adattarsi al tuo edificio.

Decidi quanti soldi puoi spendere. Ricorda di pensare al prezzo sia al prezzo che ai costi futuri.

Guarda i materiali di imballaggio che desideri utilizzare. Alcune macchine funzionano meglio con determinati film o fogli.

Chiedi informazioni sulle caratteristiche di sicurezza. Cerca cose come l'arresto automatico e i modi per fermare l'umidità o la muffa.

Confronta diverse aziende. Scegli uno con un buon nome e forti certificazioni.

Test per problemi. Assicurati che la macchina sigilla bene i sacchi e non strappano il film.

Scopri il tuo ritorno sull'investimento. La macchina giusta dovrebbe aiutare la tua azienda a crescere.

Controlla se è facile risolvere piccoli problemi. Vuoi sistemare cose come il disallineamento della borsa o le guarnizioni cattive velocemente.

Mancia: Stampa questa lista di controllo e usalo quando fai acquisti. Ti aiuterà a ricordare cosa cercare.

Consultazione di esperti

Non devi scegliere una macchina da solo. Parla con fornitori ed esperti prima di acquistare. Possono rispondere alle tue domande e dare consigli per le tue esigenze. Gli esperti possono aiutarti a abbinare la macchina al tuo prodotto e al processo di imballaggio. Potrebbero anche mostrarti come risolvere problemi comuni o suggerire aggiornamenti per risultati migliori.

Chiedi una demo o un caso di studio. Questi possono mostrarti come funziona la macchina nella vita reale. Puoi anche chiedere riferimenti da altri clienti. Questo passaggio ti aiuta a sentirti sicuro della tua scelta.

FAQ

Quali prodotti puoi impacchettare con una macchina per guarnizione di riempimento verticale?

È possibile utilizzare la macchina per le polveri, liquidi, spuntini, cereali, e piccolo hardware. Funziona in molti settori come il cibo, prodotti chimici, e forniture per animali domestici. Prova sempre prima il tuo prodotto per assicurarti che la macchina funzioni per te.

Come si mantengono una macchina per guarnizioni di riempimento verticale?

Pulisci la macchina ogni giorno e cerca parti usurate. Segui i passaggi delle cure dalla guida del tuo fornitore. Prendersi cura della macchina aiuta a durare più a lungo e mantiene la tua confezione sicura.

Puoi collegare una macchina VFFS ad altre apparecchiature?

SÌ, Puoi collegare la tua macchina VFFS alla pesatura, etichettatura, o sistemi di stampa. Questa configurazione ti aiuta a automatizzare l'imballaggio e lavorare più velocemente. Controlla sempre se le macchine lavorano insieme prima di acquistarne di nuove.

Come scegli la dimensione della borsa giusta per il tuo prodotto?

Misura il peso del tuo prodotto e quanto spazio occupa. Scegli una dimensione della borsa adatta al tuo prodotto e mantieni la spedizione al sicuro. Molte macchine ti consentono di cambiare le dimensioni delle borse per prodotti diversi.

Quali caratteristiche di sicurezza dovresti cercare?

Cerca i pulsanti di arresto di emergenza, Guardie di sicurezza, e sensori sulla macchina. Queste funzionalità aiutano a mantenere i lavoratori al sicuro e fermare gli incidenti. Le macchine con etichette di sicurezza chiare sono più facili e più sicure da utilizzare.