Wrapping food by hand can be messy, slow, and inconsistent. Enter the cling film wrapping machine, a simple device that turns this chore into a fast, सटीक, and hygienic process. From fresh sandwiches to fruits, baked goods, और अधिक, it keeps your products safe, ताजा, and ready to sell.

इस गाइड में, you’ll discover how to use a क्लिंग फिल्म रैपिंग मशीन like a pro, understand its key features, and learn tips to speed up your food packaging while cutting waste and labor. Whether you run a café, bakery, or supermarket, this machine can transform the way you handle packaging.

What Is a Cling Film Wrapping Machine?

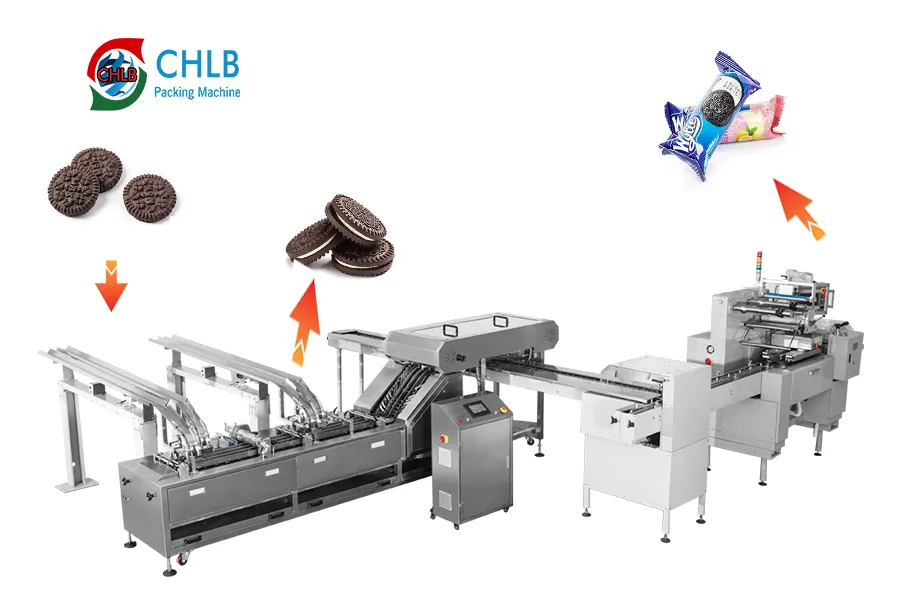

A cling film wrapping machine is a handy tool that helps you wrap food quickly and neatly. It’s a must-have in places like supermarkets, बेकरियों, butcher shops, and restaurants, where keeping food fresh and clean is a top priority. Unlike wrapping by hand, this machine creates a tight, consistent seal, protecting your products from air and germs.

Why You’ll Love Using It

Consistent Freshness: Each item is wrapped the same way, keeping it safe and fresh longer.

Saves Time: You can wrap more products in less time, freeing you up for other tasks.

Hygienic Packaging: Reduces direct contact with food, helping maintain hygiene standards.

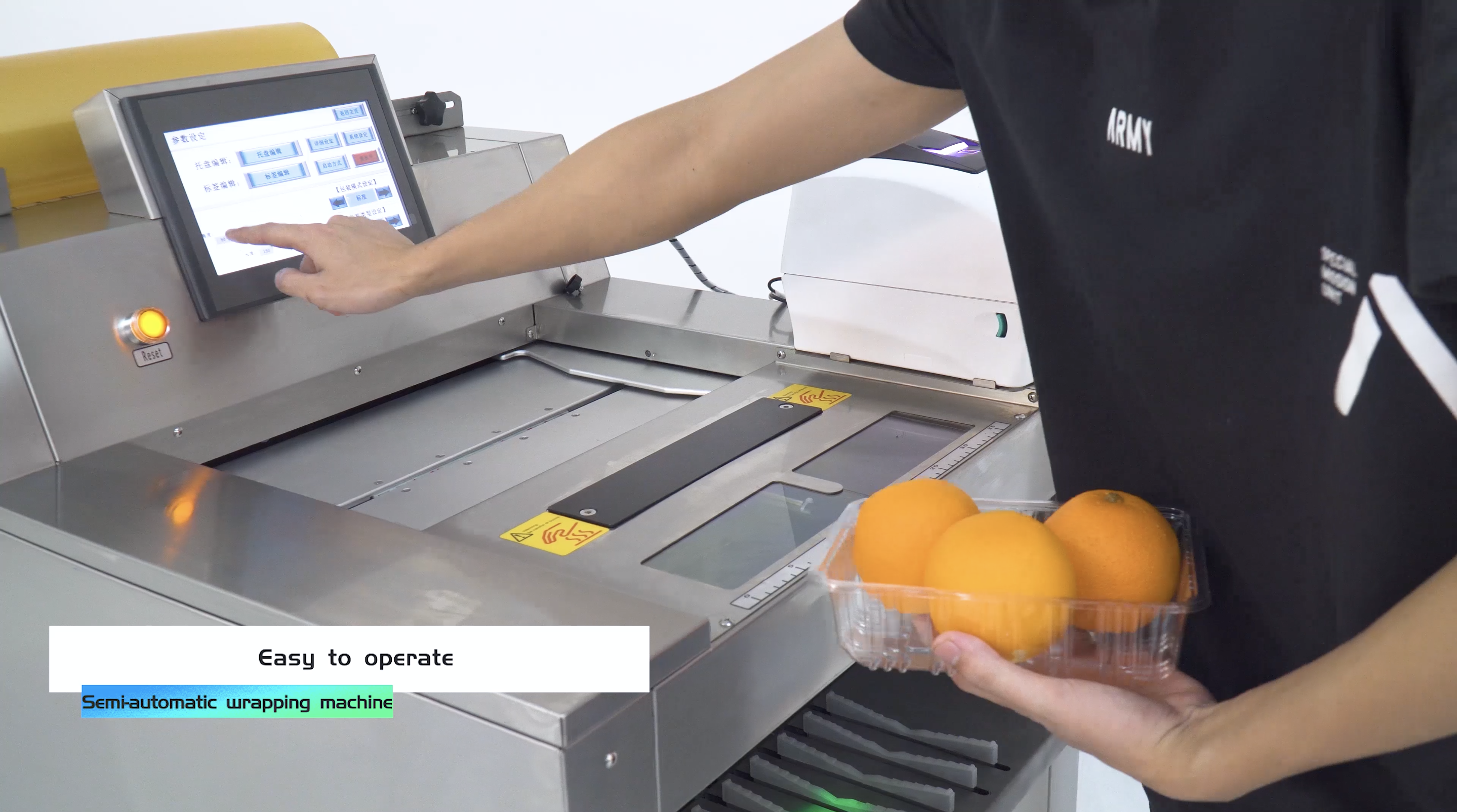

Easy to Use: Modern automatic food wrapping machines are simple to operate, even for beginners.

Think of this machine as your behind-the-scenes helper. It keeps the chicken in the grocery store neat, sandwiches in the café tidy, and fruit packs looking perfect. With an automatic food wrapping machine, you can boost efficiency, save labor costs, and impress customers with professionally wrapped products every time.

Key Components and Features of a Cling Film Wrapping Machine

To see why an automatic food wrapping machine makes packaging so efficient, it helps to understand its key parts.

Core Components

Film Roll Holder: Keeps the cling film roll ready and feeds it smoothly.

Cutting Blade: Slices the film cleanly for a perfect finish.

Sealing Plate or Hot Plate: Uses heat to lock in freshness with a strong seal.

Wrapping Platform: Supports the product so it stays steady during wrapping.

Notable Features

Adjustable film tension to fit small or large products.

Energy-saving sealing plates that cut costs and boost efficiency.

Easy-to-use control panels for fast, straightforward operation.

Durable stainless steel construction that stays clean and hygienic.

These components and features combine to make cling film wrapping machines fast, भरोसेमंद, and essential for supermarkets, बेकरियों, and restaurants. Top manufacturers are constantly improving them with compact designs, smarter automation, and eco-friendly materials to meet today’s sustainability goals.

How a Cling Film Wrapping Machine Works

A cling film wrapping machine handles the wrapping automatically, giving every food package a neat, professional look while keeping it fresh. Place your product in the machine, and it stretches, seals, and trims the film precisely without extra effort.

Why It Works So Well

Consistent Quality: Every package gets the same tight, clean seal, reducing waste and keeping food safe.

गति और दक्षता: The machine wraps items faster than manual labor, letting you handle larger volumes with less effort.

Hygienic Operation: Minimal human contact means lower contamination risk, which is essential for food safety.

Adaptable Settings: Adjustable film tension, रफ़्तार, and sealing temperature let you wrap everything from delicate pastries to heavier cuts of meat.

By automating these steps, a cling film wrapping machine saves time, cuts labor costs, and ensures your products are always presentation-ready.

Step-by-Step Guide to Using a Cling Film Wrapping Machine

Using a cling film wrapping machine might sound tricky at first, but once you get the hang of it, the process is smooth and fast. Follow these steps to wrap your food efficiently:

कदम 1: Prepare Your Food Items

Make sure each item is clean, dry, and ready for packaging. Freshness matters, so arrange them neatly on a tray or conveyor for easy handling.

कदम 2: Load the Cling Film

Place the roll of cling film onto the machine according to the manufacturer’s instructions. Ensure the film is threaded properly so it wraps evenly and doesn’t tear.

कदम 3: Set the Machine

Adjust the wrapping speed, heat (if your machine seals automatically), and size settings for your product. Modern machines often let you control these parameters digitally, giving you consistent results every time.

कदम 4: Wrap the Food

Place each item on the machine platform or conveyor. Press start and let the machine handle the wrapping. Watch how the cling film smoothly covers the product, creating a tight, professional seal.

कदम 5: Inspect and Finish

Check each wrapped item for proper sealing and appearance. Trim excess film if necessary and stack the products ready for storage or sale.

Tips for Best Results

To get the most out of your cling film wrapping machine and make your food packaging look professional, follow these simple tips:

Keep the Film Taut

A loose film can wrinkle or tear, so always make sure it’s stretched properly before wrapping. This ensures a tight seal that keeps food fresh longer.

Match Settings to Product Size

Adjust the machine’s speed, heat, or tension based on the size and shape of your food. Small items need different settings than larger trays, so test a few first to find the perfect balance.

Maintain Clean Surfaces

Wipe down the machine regularly. Dust, crumbs, or moisture can affect wrapping quality and even damage the film or food.

Rotate Stock Efficiently

Wrap and store items in the order they will be used or sold. This minimizes waste and keeps your packaging process organized.

Train Your Team

If multiple people operate the machine, consistent training ensures everyone uses the same settings and techniques. That way, every package looks professional and uniform.

Choosing the Right Cling Film Wrapping Machine for Your Business

Picking the right cling film wrapping machine depends on what you sell, how much you package, and your workspace. The right choice makes your packaging faster, neater, and more reliable.

Things to Consider

Volume of Use – Small cafés or bakeries may do well with a manual or semi-automatic model, while supermarkets and large food operations benefit from a fully automatic food wrapping machine.

मशीन का आकार – Compact machines fit tight kitchen spaces, while bigger units can handle bulk packaging with ease.

सहनशीलता – Stainless steel construction ensures your machine lasts for years and keeps food safe.

Manufacturer Support – Reputable wrapping machine manufacturers provide warranties, स्पेयर पार्ट्स, and helpful after-sales service.

Choosing the right packaging machines not only speeds up your packaging but also keeps food fresh, improves efficiency, and delights your customers.

Final Thoughts

Cling film wrapping machines make food packaging faster, cleaner, and more consistent. प्रक्रिया को स्वचालित करके, you save time, reduce waste, and ensure every product looks fresh and appealing. Whether you run a bakery, deli, or supermarket, these machines turn a routine task into a smooth, professional operation.

If you want reliable performance and smart design, the best wrapping machine manufacturers like CHLB Packaging Machine Co., लिमिटेड., offer a range of automatic food wrapping machines that deliver quality and efficiency.

👉Learn more about their solutions on the CHLB Packaging website, and find out how a single machine can transform your food packaging workflow.