Les machines d'emballage par thermoformage jouent un rôle clé dans la production moderne, transformer efficacement les films plastiques plats en barquettes et emballages répondant à des normes strictes de qualité et d'hygiène. Que vous travailliez dans l'alimentation, médical, ou secteurs industriels, connaître le fonctionnement de ces machines est essentiel pour choisir le matériel adapté à vos besoins. Cet article fournira un aperçu clair de ce qu'est une machine d'emballage par thermoformage et vous guidera tout au long de son flux de travail complet., pas à pas.

Qu'est-ce qu'une machine d'emballage par thermoformage?

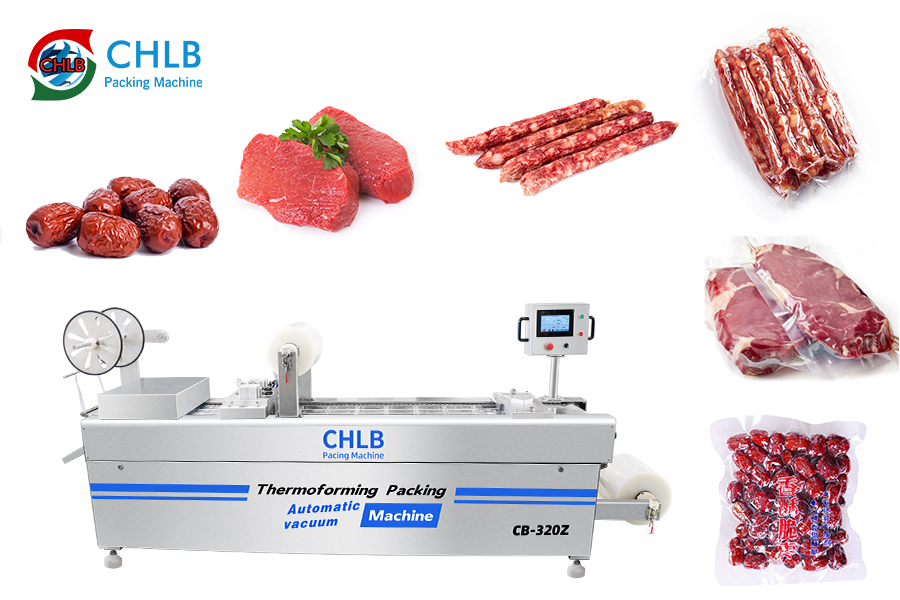

Une machine d'emballage par thermoformage est un système entièrement automatisé conçu pour convertir des rouleaux plats de film plastique en rouleaux façonnés., emballages scellés en un cycle continu. Il chauffe précisément le film de base à sa température de formage, l'étire dans un moule sous vide, pression, ou assistance à la prise, remplit les cavités formées avec du produit, puis applique et scelle une bande supérieure. Le procédé intègre le chauffage, formation, remplissage, scellage, et découpe dans un seul cadre. Parce que chaque étape est contrôlée par une logique programmable, la machine fournit des dimensions d'emballage uniformes, propriétés barrières fiables, et une intégrité d'étanchéité constante à grande vitesse.

D'un point de vue opérationnel, vous pouvez la considérer comme une ligne de production compacte conçue pour répondre à des volumes élevés, exigences d'hygiène élevées. En introduisant le film de votre choix et en définissant les paramètres clés, vous prenez le contrôle de la profondeur du pack, forme, et épaisseur du matériau. Cela vous permet de standardiser la qualité sur des milliers de paquets par heure tout en réduisant la manipulation manuelle et en respectant les réglementations strictes en matière d'emballage.

Composants clés à l'intérieur d'une machine d'emballage par thermoformage

Déroulement du film et contrôle de la tension

Cette unité maintient les rouleaux de film supérieur et inférieur et les alimente avec une tension constante. Une alimentation stable évite les plis et maintient les surfaces d'étanchéité plates. Un réglage correct de la tension du film peut réduire considérablement les défauts de scellage.Station de chauffage

Des radiateurs à quartz ou en céramique réchauffent le film inférieur à la température de formage, généralement 90 à 120 °C pour le PVC et 120 à 160 °C pour le PET ou le PP, en fonction de l'épaisseur. Un chauffage uniforme est essentiel pour éviter un amincissement inégal du matériau.Station de formage (Zone de moisissure)

Le film chauffé entre dans un moule où le vide, pression, ou un bouchon aide à le façonner en cavités. Les canaux de refroidissement dans le moule accélèrent la prise, et les moules haut de gamme peuvent former des formes complexes comme des plateaux profonds avec des coins serrés.Zone de chargement ou de remplissage

Des opérateurs ou des systèmes de dosage automatisés placent le produit dans les poches formées. Dans les usines alimentaires, cette zone est souvent enfermée dans un environnement hygiénique ou contrôlé pour maintenir la sécurité du produit.Station de scellage

Le meilleur film (souvent imprimé ou plastifié) couvre les poches remplies. Scellez-le à chaud et sous pression au film inférieur.. Dans les packs médicaux, les paramètres d'étanchéité sont validés pour OIN 11607 pour garantir la stérilité.Station de découpe ou de poinçonnage

La machine coupe les paquets individuels ou les laisse en bandes perforées. La découpe de précision réduit les déchets et améliore l'apparence des étagères.

Chaque module est contrôlé par un automate avec température, pression, et rétroaction sur le timing. L'interface permet aux opérateurs d'affiner les paramètres pour les adapter à différents films et produits. Un étalonnage cohérent des capteurs peut augmenter la disponibilité de la ligne jusqu'à 5 à 10 % par an.

Comment fonctionne une machine d'emballage par thermoformage

Chauffage et préparation du film

Le processus commence lorsque le film inférieur – souvent du PET ou du PP – entre dans la zone de chauffage.. Il est chauffé à 120-160 °C, en fonction de l'épaisseur, ce qui ramollit suffisamment le matériau pour le formage tout en conservant ses propriétés barrières. Un contrôle minutieux de chaque zone de température peut grandement améliorer l'uniformité de l'épaisseur et contribuer à réduire considérablement la consommation d'énergie par rapport à un chauffage incontrôlé..

Former les cavités

Une fois que le film atteint la bonne température, il entre en douceur dans la station de formage. Ici, vide, pression, ou la technologie d'assistance au branchement façonne le film en cavités ou plateaux précis. La sélection de la bonne méthode garantit des murs et des bords précis, ce qui est particulièrement important si vous produisez des emballages de grande valeur ou bien ajustés.

Remplissage du produit

Dès que les cavités se forment, ils se rendent directement à la zone de remplissage. En fonction de votre configuration, le dosage peut être automatisé ou manuel. Dans les usines alimentaires, cette zone est souvent enfermée dans un environnement hygiénique ou contrôlé pour maintenir la sécurité des produits et réduire le risque de contamination. Garder cette section propre peut réduire considérablement le risque de rejet de paquets par rapport aux zones de chargement ouvertes..

Rinçage sous vide ou au gaz (si nécessaire)

Avant de sceller, la machine peut évacuer l'air des cavités ou le remplacer par un mélange gazeux protecteur. Cette étape facultative permet de prolonger la durée de conservation, protéger les objets délicats, et une croissance microbienne lente. Il peut également être entièrement contourné pour les produits qui ne nécessitent pas d'atmosphère modifiée..

Scellement avec le film supérieur

Après remplissage et toute étape de vide ou de rinçage au gaz, un film supérieur recouvre le produit et est scellé au film inférieur formé par chaleur et pression. L'équilibre entre la température, temps de séjour, et la tension de la toile est critique. Lorsque ces paramètres sont optimisés, vous obtenez moins de défauts de scellage et maintenez l’intégrité constante de l’emballage même à des vitesses plus élevées.

Découpe et finition des packs

La bande scellée entre ensuite dans la station de découpe, où les lames ou les matrices de précision séparent les paquets individuels. Une coupe nette améliore à la fois l’apparence et la consistance. Une découpe de haute précision peut réduire considérablement les déchets de film et les coûts de matériaux au fil du temps, ce qui est important pour les longues séries de production.

Surveillance et contrôle

Tout au long de ces étapes, un automate central et un système de capteurs suivent la température, niveaux de vide, et tension web en temps réel. Vous pouvez ajuster les paramètres sur le panneau de commande pendant la production, ce qui aide à stabiliser la qualité, réduire les temps d'arrêt, et maintenir une production stable tout au long des équipes.

Principaux types de procédés de thermoformage et leurs applications

UN machine d'emballage par thermoformage fonctionne en chauffant un film plastique plat jusqu'à ce qu'il ramollisse, puis façonnez-le en cavités ou en plateaux qui correspondent aux exigences du produit. La méthode de formage que vous choisissez affecte la profondeur du plateau, épaisseur de paroi, et la précision globale. Connaître ces différences vous aide à sélectionner la bonne configuration de machine et à optimiser l'utilisation des matériaux..

Formage sous vide

En formage sous vide, le film chauffé est placé sur un moule, et l'air est aspiré pour que le film épouse parfaitement la forme du moule. Cette méthode est simple et rentable, car l'outillage est plus simple. Il fonctionne mieux pour les plateaux ou les emballages peu profonds où l'épaisseur de la paroi est relativement uniforme..

Vous pouvez exécuter le formage sous vide à des vitesses modérées tout en obtenant des résultats cohérents., ce qui le rend adapté à la production en grand volume de formes simples. La simplicité de cette méthode signifie également que la maintenance et la configuration sont plus rapides par rapport aux techniques de formage plus complexes..

Applications typiques: boîtes à repas jetables, plateaux de restauration rapide, emballage alimentaire léger, et pièces industrielles légères.

Formage sous pression

Le formage sous pression s'appuie sur le formage sous vide en appliquant une pression d'air supplémentaire ou une force mécanique par le haut.. Cela pousse le film plus étroitement contre le moule, ce qui vous permet de produire des cavités et des formes plus profondes avec une plus grande variation d'épaisseur de paroi.

Par rapport au formage sous vide, Le formage sous pression permet d'obtenir une précision dimensionnelle plus élevée et de réduire les points faibles où le film pourrait s'étirer trop finement.. Il est particulièrement utile lorsque le produit nécessite une protection précise ou lorsque vous utilisez des films plus épais pour plus de durabilité..

Applications typiques: plateaux profonds, emballage pour dispositifs médicaux, et des produits alimentaires haut de gamme qui nécessitent à la fois un attrait visuel et une protection..

Formage assisté par prise

Le formage assisté par bouchon ajoute un bouchon mécanique ou pneumatique qui pousse le film dans le moule pendant le formage sous vide ou sous pression.. Cela garantit que l'épaisseur de la paroi reste constante, même pour les formes profondes ou complexes..

Cette méthode est idéale pour les peaux délicates, de grande valeur, ou produits lourds pour lesquels une épaisseur de paroi uniforme est essentielle. Le bouchon réduit la contrainte du matériau, aide à maintenir la forme, et améliore les performances d'étanchéité dans l'emballage final.

Applications typiques: viandes sous vide, plateaux médicaux profonds, plateaux cosmétiques de précision, et composants industriels fragiles.

Méthodes combinées ou hybrides

De nombreuses machines de thermoformage utilisent une combinaison de ces techniques pour équilibrer la vitesse, profondeur, et épaisseur de paroi. Par exemple, le vide plus la pression ou l'assistance au branchement plus la pression peuvent être appliqués, en particulier lors du traitement de films multicouches ou barrières.

Bien que les coûts d'outillage soient plus élevés pour les méthodes combinées, ils améliorent l'efficacité des matériaux et produisent des emballages plus cohérents, en particulier dans la production en grand volume où la précision et la qualité sont cruciales. Vous pouvez également faire fonctionner ces machines à des vitesses plus élevées sans compromettre la forme ou l'uniformité des murs..

Réflexions finales

Les machines d'emballage par thermoformage suivent une séquence claire : la chaleur, formulaire, remplir, (aspiration ou rinçage au gaz en option), joint, et couper. Quand vous comprenez ce flux de travail, vous pouvez voir comment ces machines offrent des performances cohérentes, hygiénique, et des packs de haute qualité à grande échelle. À CHLB, nous concevons des machines qui optimisent l'utilisation des matériaux et l'épaisseur des parois, vous aidant à obtenir une production fiable avec une réduction des déchets.

Si vous envisagez une nouvelle machine ou une mise à niveau de votre ligne, notre équipe à CHLB peut aider. Nous fournissons des spécifications détaillées, données de performances, et des conseils adaptés à vos besoins de production. En choisissant la bonne solution d'emballage par thermoformage, vous assurez l'efficacité, sécurité des produits, et présentation professionnelle pour chaque pack qui quitte votre établissement.