Cada producto que llega al lineal de una tienda en perfectas condiciones cuenta una historia sobre su packaging. en comida, médico, y sectores industriales, Las máquinas de envasado termoformado se encuentran en el centro de esa historia.. Ellos dan forma, sello, y proteger las mercancías a alta velocidad, lo que los hace esenciales para empresas como la suya que necesitan una calidad constante y una producción escalable.

En este artículo, aprenderás qué es una máquina envasadora termoformadora, Descubra ocho fabricantes líderes a nivel mundial., y vea consejos prácticos para elegir el socio adecuado para fortalece tu línea de empaque.

Arriba 8 Fabricantes de máquinas de envasado termoformado en el mundo

Tabla de comparación rápida

Fabricante | País | Fundado | Productos principales | Ventajas de fabricación |

|---|---|---|---|---|

ILLIG Maschinenbau GmbH & Co. KG | Alemania | 1946 | Máquinas termoformadoras, moldes, líneas de embalaje | Alta precisión, energéticamente eficiente, tecnología avanzada de moldes, soporte de servicio global |

Kiefel GmbH | Alemania | 1955 | Máquinas termoformadoras, líneas de extrusión, soluciones de automatización | Alta automatización, flexibilidad, R significativa&inversión, Amplia red de servicio global. |

Grupo MULTIVAC | Alemania | 1961 | Máquinas de envasado termoformado, sistemas de envasado al vacío, Unidades de mapa | Alto rendimiento, fiabilidad, interfaces fáciles de usar, adecuado para diversas aplicaciones |

Grupo de máquinas marrones (BMG) | EE.UU | 1985 | Máquinas termoformadoras rígidas, soluciones de embalaje industrial | Adecuado para materiales gruesos, diseño robusto, alta flexibilidad, fuerte soporte de ingeniería |

GABLER Thermoform GmbH & Co. KG | Alemania | 1974 | Máquinas termoformadoras de envases de alimentos, sistemas de automatización | Conformación de alta precisión, cambio rápido de molde, diseño energéticamente eficiente, fuerte soporte técnico |

GEISS AG | Alemania | 1948 | Máquinas termoformadoras, Sistemas de procesamiento CNC | Alta confiabilidad, adaptable a diferentes materiales, equilibrio entre eficiencia y costo, fácil mantenimiento |

AUTO GRUPO COMI S.R.L | Italia | 1973 | Máquinas termoformadoras, Sistemas de embalaje MAP | Diseño modular, alta flexibilidad, cumplimiento de las normas europeas, fuerte soporte técnico |

Embalajes ULMA | España | 1957 | Máquinas termoformadoras, sistemas de embalaje | Interfaces fáciles de usar, diseño energéticamente eficiente, alta automatización, adecuado para diversas aplicaciones |

ILLIG Maschinenbau GmbH & Co. KG (Alemania)

Descripción general de la empresa: Fundado en 1946, con sede en Heilbronn, Alemania. ILLIG se ha convertido en un líder mundial en tecnología de termoformado, suministrando máquinas a más 100 países. La empresa apuesta por la innovación, fiabilidad, y asociaciones con clientes a largo plazo.

Productos principales: Máquinas termoformadoras de alta velocidad para alimentos, médico, y embalajes de bienes de consumo.

Ventajas de fabricación: Precisión y repetibilidad excepcionales, marco y componentes duraderos, tecnología de molde avanzada para formas complejas, sistemas energéticamente eficientes, y un sólido soporte postventa en todo el mundo.

Kiefel GmbH (Alemania)

Descripción general de la empresa: Establecido en 1948, con sede en Freilassing, Alemania. Kiefel es reconocida por su experiencia en automatización y soluciones de embalaje flexible, sirviendo a industrias desde la alimentaria hasta la médica y la automotriz. La empresa invierte fuertemente en R&D mantenerse a la vanguardia de la tecnología de embalaje.

Productos principales: Máquinas termoformadoras, líneas de extrusión, y soluciones de embalaje totalmente automatizadas.

Ventajas de fabricación: Sistemas de control de alto rendimiento con regulación precisa del ciclo., automatización robusta, Capacidades de formación flexibles para productos variados., y soporte de servicio global integral que garantiza un tiempo de inactividad mínimo.

Grupo MULTIVAC (Alemania)

Descripción general de la empresa: Fundado en 1961, con sede en Wolfertschwenden, Alemania. MULTIVAC es líder mundial en soluciones integradas de embalaje, conocido por la innovación y la ingeniería de alta calidad. Tiene una fuerte presencia en envases alimentarios y médicos a nivel mundial..

Productos principales: Máquinas de termoformado, llenado y sellado, sistemas de envasado al vacío, MAPA (Embalaje de ambiente modificado) maquinas.

Ventajas de fabricación: Rendimiento confiable de alto volumen, interfaces fáciles de usar, diseños que cumplen con las normas higiénicas para productos sensibles, Aplicaciones versátiles con calidad constante..

Grupo de máquinas marrones (BMG) (EE.UU)

Descripción general de la empresa: Fundado en 1985, con sede en Kansas City, EE.UU. BMG se especializa en máquinas termoformadoras de gran espesor para envases industriales y de consumo.. La empresa se centra en diseñar máquinas duraderas que puedan manejar requisitos de producción exigentes..

Productos principales: Máquinas termoformadoras rígidas para bandejas, contenedores, y otros embalajes industriales.

Ventajas de fabricación: Personalizable para materiales gruesos y rígidos., construcción robusta para tiradas de producción largas, flexibilidad para diversas formas de productos, y un sólido soporte de ingeniería para aplicaciones complejas.

GABLER Thermoform GmbH & Co. KG (Alemania)

Descripción general de la empresa: Fundado en 1959, con sede en Lauf, Alemania. GABLER es conocido por sus máquinas formadoras de alta precisión y sus diseños energéticamente eficientes.. La empresa sirve comida., médico, y sectores de bienes de consumo en todo el mundo.

Productos principales: Máquinas termoformadoras para bandejas de comida., embalaje medico, y bienes de consumo.

Ventajas de fabricación: Mínimo desperdicio de material gracias a una conformación precisa, Sistemas de cambio rápido de troqueles para turnos de producción más rápidos., diseños energéticamente eficientes, alta precisión de conformado, y fuerte soporte técnico.

GEISS AG (Alemania)

Descripción general de la empresa: Establecido en 1980, con sede en Pforzheim, Alemania. GEISS se especializa en soluciones de termoformado de volumen medio a alto, Ofreciendo máquinas flexibles adecuadas para una amplia gama de materiales y productos..

Productos principales: Máquinas termoformadoras con manipulación flexible de materiales., caza de focas, y capacidades de corte.

Ventajas de fabricación: Rendimiento confiable de conformado y sellado, adaptable a diferentes espesores de película, eficiencia y costo equilibrados, y mantenimiento sencillo para operaciones continuas.

AUTO GRUPO COMI S.R.L (Italia)

Descripción general de la empresa: Fundado en 1964, con sede en Italia. AMUT-COMI está especializada en maquinaria de embalaje rígido y flexible. La empresa enfatiza los diseños modulares para permitir una fácil adaptación a diversos requisitos de producción y personalización..

Productos principales: Máquinas termoformadoras al vacío., MAPA, y aplicaciones de embalaje estándar.

Ventajas de fabricación: Construcción modular para fácil actualización y personalización., Soluciones versátiles para diferentes tipos de productos., Cumplimiento de las normas europeas de diseño e higiene., y un sólido soporte técnico para clientes globales.

Embalajes ULMA (España)

Descripción general de la empresa: Establecido en 1957, Con sede en Oñati, España. ULMA es un actor clave en soluciones de envasado alimentario y no alimentario, conocido por sus líneas de termoformado totalmente automatizadas y su innovación en tecnología de envasado.

Productos principales: Máquinas termoformadoras totalmente automatizadas que integran el conformado., relleno, y sellado.

Ventajas de fabricación: Interfaces y operación fáciles de usar, diseños centrados en la higiene, producción energéticamente eficiente, Automatización confiable para producción de alto volumen., y calidad constante del producto.

Máquina de envasado termoformado y sus tipos

A máquina de envasado termoformado es una herramienta que se utiliza para convertir láminas de plástico en formas de embalaje precisas. Se empieza calentando la película plástica hasta que se vuelva suave y flexible.. Luego, la máquina forma cavidades con la lámina calentada utilizando moldes., presión, o vacío. Una vez que las formas estén listas, Puedes llenar las cavidades con tu producto., sellarlos con una tapa o film, y recortar el material sobrante. Este proceso le brinda paquetes terminados que están listos para enviar o exhibir..

Tipos de máquinas de envasado termoformado

Cuando miras las máquinas de envasado termoformado, Es importante comprender que se pueden agrupar según cómo manejan el paquete después de formarlo.. Esta clasificación se centra en la forma en que la máquina conserva y protege el producto dentro del paquete.. Saber esto te ayuda seleccione una máquina que se adapta a sus necesidades específicas, ya sea que esté envasando alimentos frescos, productos refrigerados, o artículos secos.

Máquina de envasado al vacío termoformado

Después de formar, la máquina elimina el aire (crea un vacío) o llena el paquete con gas antes de sellar

Comúnmente utilizado para productos frescos o alimentos perecederos como la carne, queso, y mariscos

Ayuda a prolongar la vida útil y mantener la calidad del producto al reducir el oxígeno dentro del paquete.

MAPA (Envasado en atmósfera modificada) Máquina de termoformado

Después de formar, la máquina llena el paquete con gases protectores como el nitrógeno (N₂) o dióxido de carbono (CO₂)

Prolonga la vida útil de los alimentos cocinados., productos semiacabados, y alimentos frescos refrigerados

Ideal cuando necesita envasado en atmósfera controlada para conservar el sabor., color, y frescura

Estándar / Máquina termoformadora sin vacío

Solo realiza formación y sellado de bandejas o cavidades., sin vacío ni inyección de gas

A menudo utilizado para consumibles médicos, bandejas electrónicas, golosinas, y otros productos secos

Proporciona una solución más sencilla y rentable cuando no es necesario el envasado al vacío o con gas.

Cómo elegir fabricantes de máquinas envasadoras termoformadoras

Evaluar la experiencia y la reputación de la industria

Elegir un fabricante con una sólida trayectoria es esencial para una producción fiable. Necesita un socio que tenga experiencia demostrada en máquinas de termoformado para su sector específico, ya sea comida, médico, o embalaje industrial. Las empresas experimentadas tienen prácticas de ingeniería refinadas., flujos de trabajo probados, y soporte posventa confiable. Seleccionando un fabricante conocido por su calidad., Reduce los riesgos operativos y garantiza que su proceso de embalaje se desarrolle sin problemas..

Evaluar las capacidades técnicas y la flexibilidad de la máquina

El rendimiento y la adaptabilidad de las máquinas son factores clave. Busque características como opciones de conformado ajustables, sistemas de cambio rápido de molde, y diseños energéticamente eficientes. Estos le permiten cambiar de producto o formato de embalaje rápidamente sin perder eficiencia.. La automatización moderna y los sistemas de control intuitivos también minimizan los errores del operador., ahorrando tiempo y asegurando calidad constante del producto. La flexibilidad aquí afecta directamente su capacidad para satisfacer las demandas cambiantes del mercado..

Considere la red de soporte y las opciones de personalización

La personalización y el soporte global confiable pueden marcar una diferencia significativa. Los fabricantes con sólidos equipos de servicio lo ayudan a solucionar problemas rápidamente, minimizando el tiempo de inactividad. Las máquinas modulares o configurables le permiten adaptar el sistema a sus necesidades de embalaje., ya sea vacío, MAPA, o formación estándar. Trabajar con un socio que comprenda sus objetivos de producción garantiza una mayor eficiencia, calidad consistente, y competitividad a largo plazo.

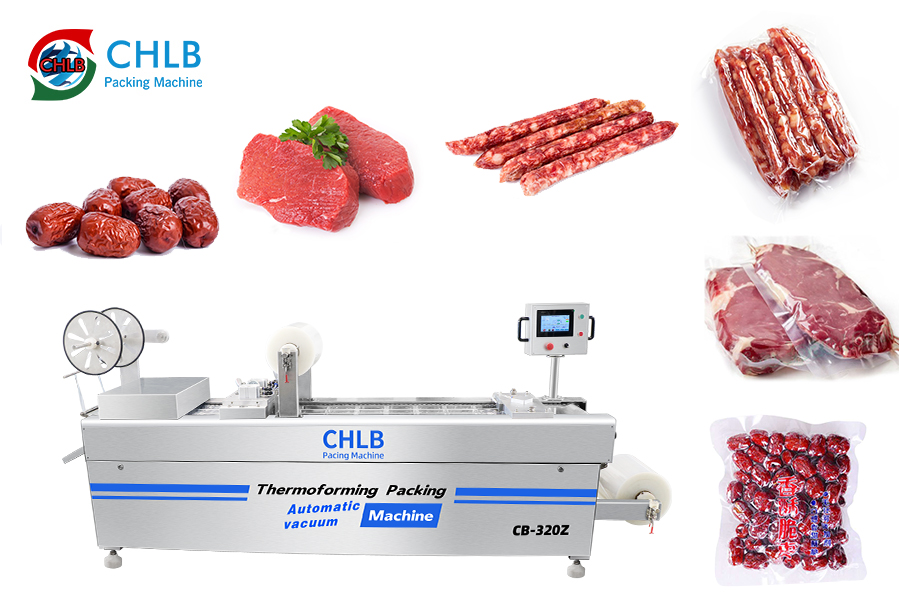

Asóciese con CHLB

Trabajando con CHLB significa ganar un socio que comprenda sus presiones reales de producción. Nuestras máquinas de envasado termoformado están construidos para la flexibilidad, cambios rápidos, y formación precisa, para que puedas manejar diversos productos sin perder tiempo. También proporcionamos datos técnicos transparentes., para que siempre sepas qué esperar de cada modelo.

Más allá de las propias máquinas, Nos centramos en un servicio receptivo y una entrega rápida de repuestos para minimizar el tiempo de inactividad.. Te beneficiarás del apoyo a la formación, garantías claras de rendimiento, y opciones para personalizar las profundidades de formado, anchos de película, o métodos de sellado para satisfacer sus necesidades exactas. Si está preparado para optimizar la producción y mejorar la calidad del embalaje, llegar a CHLB hoy para discutir la solución que mejor se adapta a su negocio.