Envolver la comida a mano puede ser desordenado, lento, e inconsistente. Ingrese la máquina de envoltura de película porta, un dispositivo simple que convierte esta tarea en un ayuno, preciso, y proceso higiénico. Desde sándwiches frescos hasta frutas, productos horneados, y más, Mantiene sus productos seguros, fresco, y listo para vender.

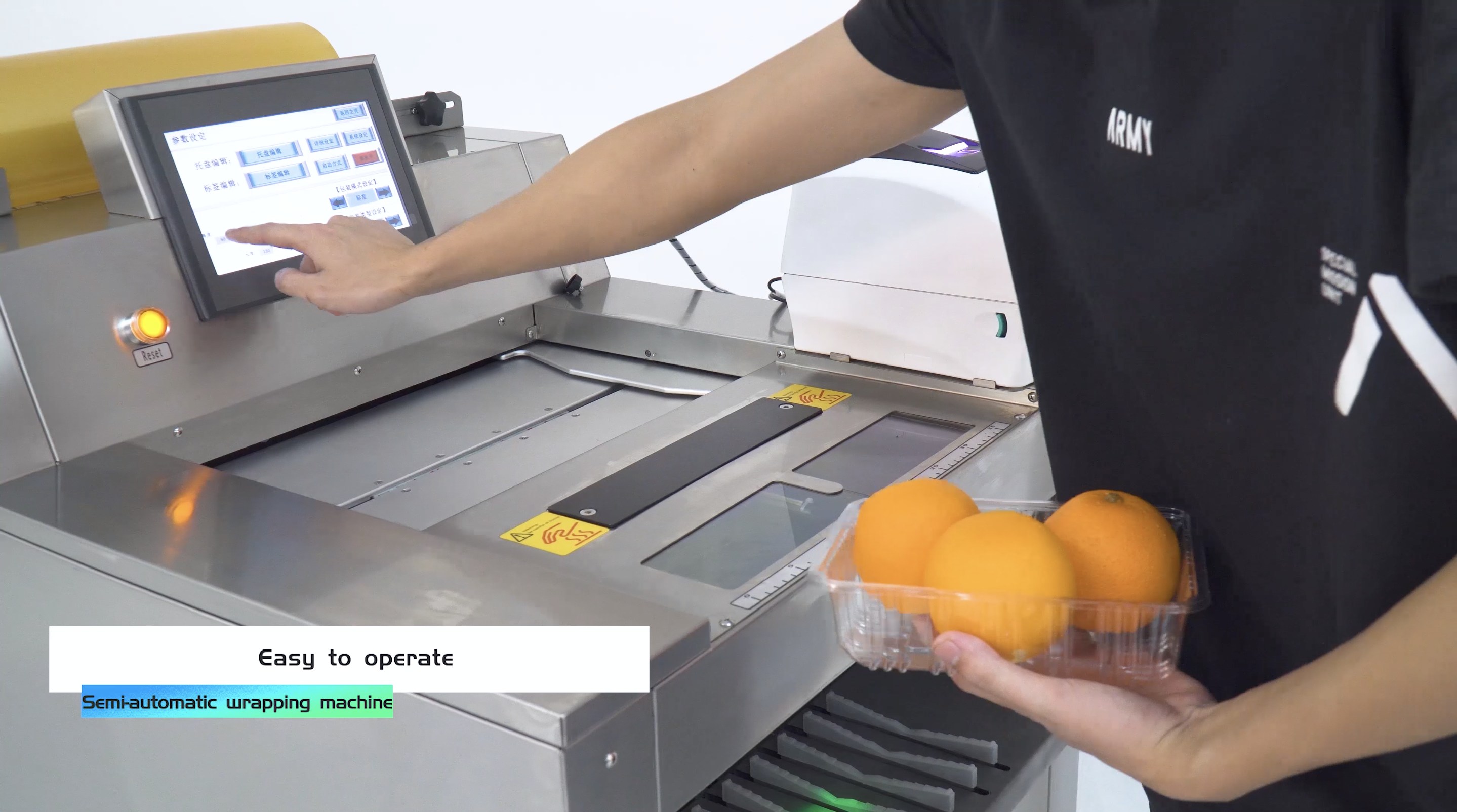

En esta guía, Descubrirás cómo usar un máquina para envolver film transparente como un profesional, Comprender sus características clave, y aprenda consejos para acelerar su empaque de alimentos mientras corta el desperdicio y el trabajo. Si corres un café, panadería, o supermercado, Esta máquina puede transformar la forma en que maneja el embalaje.

Paso 1: Prepare la máquina y cargue la película adhesiva

Antes de empezar a envolver comida, preparar la máquina es el primer paso y el más crítico. Omitir este paso puede causar sellos deficientes., envoltura desigual, o incluso dañar la máquina, que definitivamente quieres evitar.

Verificar el estado de la máquina

Comience siempre inspeccionando la máquina en busca de daños visibles., tornillos flojos, o piezas desgastadas. Revisar los rodillos de película., elementos calefactores, y el panel de control. Incluso el polvo más pequeño en la barra de sellado afecta la calidad del envoltorio.. Si su máquina tiene ajuste automático de tensión, Asegúrese de que los sensores respondan. Encima 30% de los problemas de envoltura se deben a un mantenimiento deficiente, así revisar tu equipo te ahorra problemas posteriores.

Instale el rollo de película adhesiva

Instalar correctamente el rollo de film transparente es fundamental. Asegúrese de que la película se desenrolle suavemente sin resistencia.. Para un estándar 30 rollo de cm, alinee el borde directamente en el área de sellado. La instalación incorrecta puede causar arrugas o sellos parciales., comprometiendo la seguridad alimentaria. Utilice películas de alta calidad con espesor constante (8–12 micras). Las películas más gruesas proporcionan sellos más fuertes, pero es posible que necesiten un ligero ajuste de temperatura..

Ajustar la configuración de la máquina

Las máquinas envolvedoras modernas ofrecen múltiples configuraciones ajustables. Deberías comprobar y configurar:

- Temperatura de sellado: Más alto para alimentos espesos o húmedos, inferior para artículos delicados.

- Velocidad de envoltura: Las velocidades más rápidas aumentan la productividad pero pueden reducir la tensión del envoltorio.

- Tensión de la película: Controla qué tan cómodamente se adhiere la película al producto..

Por ejemplo, cuando envuelves carne fresca o queso, una temperatura ligeramente más alta (alrededor de 120-130°C) asegura un sello fuerte. Para pasteles delicados, Mantenga la temperatura entre 90 y 100 °C para evitar que se derrita o se deforme.. Ajustar estos parámetros adecuadamente reduce el desperdicio de producto y garantiza una calidad constante para su línea de producción..

Paso 2: Cargue productos alimenticios y comience a envolver

Una vez que su máquina esté preparada, es hora de cargar la comida. La carga adecuada garantiza un embalaje uniforme y evita daños a los artículos que está empaquetando..

Seleccione alimentos adecuados

No todos los alimentos son ideales para envolver con film transparente. Deberías centrarte en:

- Frutas y verduras precortadas

- Sándwiches y comidas preparadas

- Carne, pez, y queso

- Productos de panadería

Los alimentos con alto contenido de humedad o formas irregulares pueden requerir configuraciones específicas o bandejas adicionales para mantener su forma.. Por ejemplo, si envuelves queso tierno, Es posible que necesites una bandeja liviana o una lámina de soporte para evitar aplastarla durante el envoltorio..

Organizar los alimentos correctamente

Organice sus artículos de forma ordenada en el transportador o en la bandeja de embalaje.. Evite la superposición de elementos, ya que esto puede causar un sellado desigual o aire atrapado. Separe cada elemento a una distancia de 2 a 3 cm para permitir que la película se ajuste a su forma.. Al empaquetar varios artículos, apilar en capas uniformes para mayor estabilidad. La disposición correcta le ayuda a evitar fallos en los sellos en su línea de producción..

Iniciar el proceso de envoltura

Con la comida arreglada, enciende tu máquina. Alimentación de máquinas automáticas, envoltura, y sellar artículos en un solo ciclo. Supervise los primeros ciclos para garantizar la alineación y el sellado adecuado.. Ajuste la tensión o la velocidad de la película si nota arrugas o bordes sueltos.. Verifique cada 50 a 100 artículos para mantener una calidad constante en toda su producción.

Paso 3: Inspeccionar alimentos envueltos y Garantizar la calidad

Verifique la integridad del sello

Examine la línea de sellado de cerca. un fuerte, El sello uniforme evita que entre aire., humedad, o que entren contaminantes. Los sellos deficientes a menudo aparecen arrugados., roto, o incompleto. Presione suavemente a lo largo del borde para confirmar la adhesión.. Utilice ajustes de la máquina para calor y presión si es necesario.. Los sellos aceptables deben soportar de 2 a 3 kg de tracción suave..

Inspeccionar la apariencia de la película

Asegúrese de que la película esté suave., transparente, y libre de burbujas o lágrimas. Las arrugas o el aire atrapado pueden indicar problemas de tensión o alineación.. Ajuste la velocidad de alimentación o la tensión si es necesario. El uso de películas de alta calidad reduce los defectos. Sus artículos empaquetados deben verse tan atractivos como frescos.

Almacene productos envueltos de forma segura

Transfiera los productos envueltos a un lugar de almacenamiento adecuado inmediatamente.. refrigerar productos perecederos (0–4°C) y almacene los artículos estables a temperatura ambiente, evitando la luz solar directa o la alta humedad. El almacenamiento adecuado mantiene la integridad del sello y prolonga la vida útil. Rotar el stock por primera vez, base de primero en salir Mantenga la comida fresca.

Paso 4: Limpiar y mantener la máquina

Limpiar la máquina a fondo

Después de cada ciclo de producción, Limpie su máquina para evitar que los residuos de alimentos se peguen a los rodillos o a las barras selladoras.. Utilice un paño suave con un detergente suave y evite materiales abrasivos que puedan rayar los componentes.. Si manipula carne o pescado crudo, considere desinfectar con soluciones seguras para los alimentos para prevenir el crecimiento bacteriano. La limpieza regular también prolonga la vida útil de los sensores y controles electrónicos..

Lubricar y revisar piezas

La lubricación es fundamental para piezas móviles como las cintas transportadoras., rodillos, y engranajes. Utilice lubricantes de calidad alimentaria para evitar la contaminación.. Compruebe las correas y los rodillos en busca de signos de desgaste., y reemplazarlos si es necesario. Una máquina bien lubricada funciona mejor, produce un envoltorio más consistente, y reduce el riesgo de averías para usted.

Programar mantenimiento regular

Además de la limpieza diaria, programar el mantenimiento preventivo al menos cada 3 a 6 meses, dependiendo de la frecuencia con la que uses la máquina. Esto incluye la verificación de componentes eléctricos., sensores de prueba, e inspeccionar los elementos calefactores.

Muchos fabricantes recomiendan un servicio profesional una vez al año para mantener el máximo rendimiento.. Las máquinas que reciben mantenimiento preventivo regular tienen una tasa de tiempo de inactividad entre un 25 % y un 30 % menor en comparación con aquellas que no tienen revisiones programadas.. Seguir esta rutina te ahorrará tiempo y dinero a largo plazo..

Pensamientos finales

Máquinas envolvedoras de film transparente hacer que el envasado de alimentos sea más rápido, limpiador, y más consistente. Automatizando el proceso, Ahorras tiempo, reducir el desperdicio, y asegúrese de que cada producto se vea fresco y atractivo. Si diriges una panadería, fiambres, o supermercado, Estas máquinas convierten una tarea de rutina en un suave, operación profesional.

Si desea un rendimiento confiable y un diseño inteligente, Los mejores fabricantes de máquinas de envoltura como Chlb Packaging Machine Co., Limitado., Ofrecer una gama de máquinas automáticas de envoltura de alimentos que ofrecen calidad y eficiencia.

👉Obtenga más información sobre nuestras soluciones en el Sitio web de embalaje de chlb, Y descubra cómo una sola máquina puede transformar su flujo de trabajo de envasado de alimentos.